Difference between revisions of "2019 Shapeoko 2 Refurbishment"

| Line 28: | Line 28: | ||

[[File:General_Shapeoko_Device_Cables.jpg]] | [[File:General_Shapeoko_Device_Cables.jpg]] | ||

| − | Note: The Spindle Power cable has a modification. The end connector is not common. So, a new connector has be added as a matched pair with screw terminal. The use of screw terminal connectors makes "cutting" of wiring less likely and allows reuse of connectors. The connectors do not require soldering and allow for rewiring without need to "get" new connectors or "solder" lines. A lot of wiring repairs have inline splices that cause later difficulties. The screw | + | Note: The Spindle Power cable has a modification. The end connector is not common. So, a new connector has be added as a matched pair with screw terminal. The use of screw terminal connectors makes "cutting" of wiring less likely and allows reuse of connectors. The connectors do not require soldering and allow for rewiring without need to "get" new connectors or "solder" lines. A lot of wiring repairs have inline splices that cause later difficulties. The screw terminals would allow entire wiring replacement. |

== Goal 1: Completion == | == Goal 1: Completion == | ||

Revision as of 08:44, 25 June 2019

Contents

- 1 General Information

- 1.1 Goal 1: Shapeoko 2 Device Refurbishment

- 1.2 Goal 1: Placement of Custom 3D Printed Parts

- 1.3 Goal 1: Rewiring

- 1.4 Goal 1: Completion

- 1.5 Goal 2: Controller System

- 1.6 Goal 2: Controller Description

- 1.7 Goal 2: Controller Box

- 1.8 Goal 2: Front Panel Build

- 1.9 Goal 2: Rear Panel Build

- 1.10 Goal 2: Electronics

- 1.11 Goal 2: Controller Box Assembly

- 1.12 Goal 2: E-Stop pendant

- 1.13 Goal 2: Power Box

- 1.14 General Layout of Refurbished Shapeoko 2 and GRBL Controller

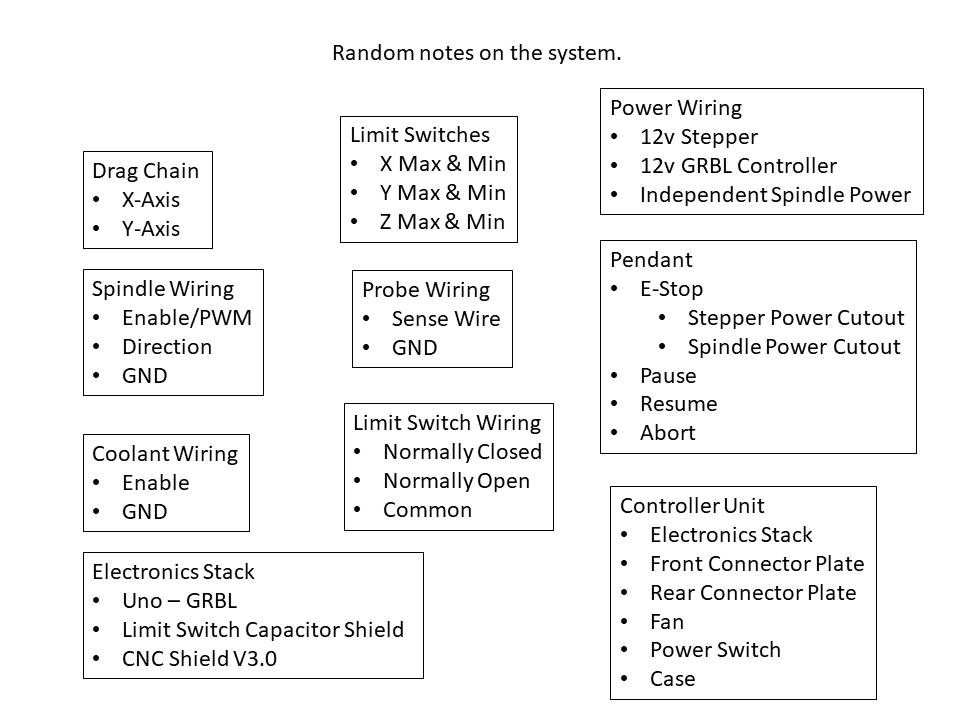

- 1.15 General Notes:

General Information

Link to 2016 Madness Shapeoko_Repair_Madness_2016

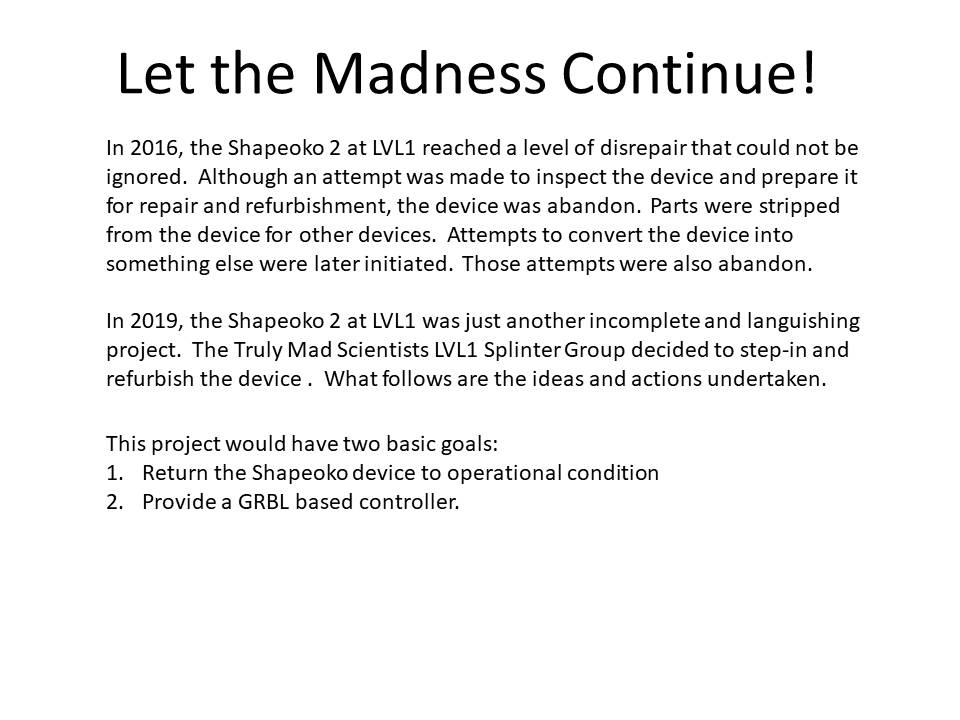

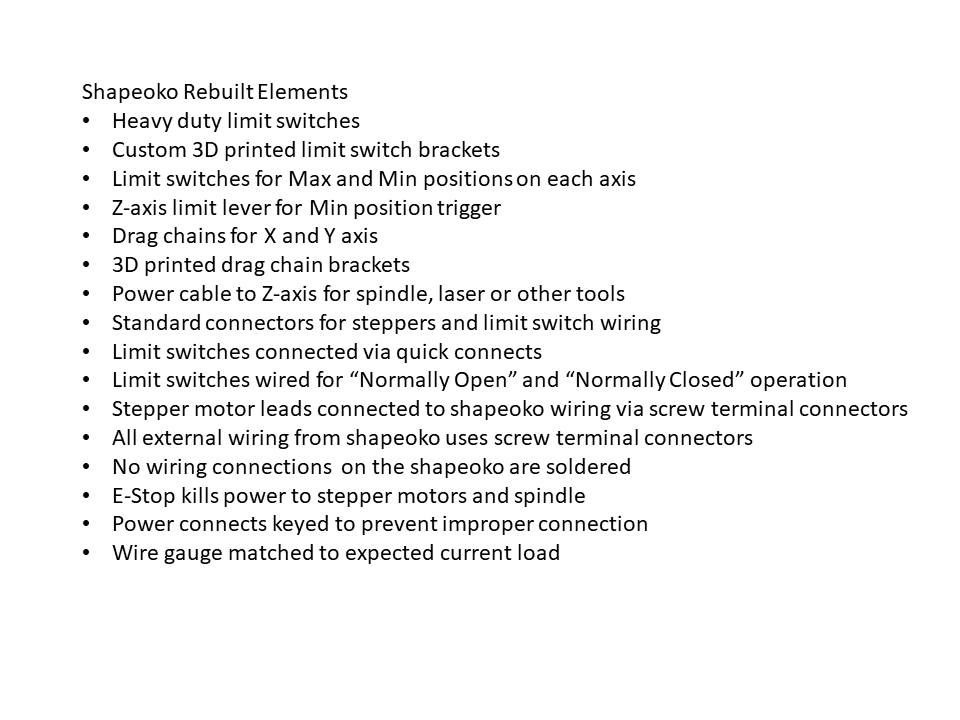

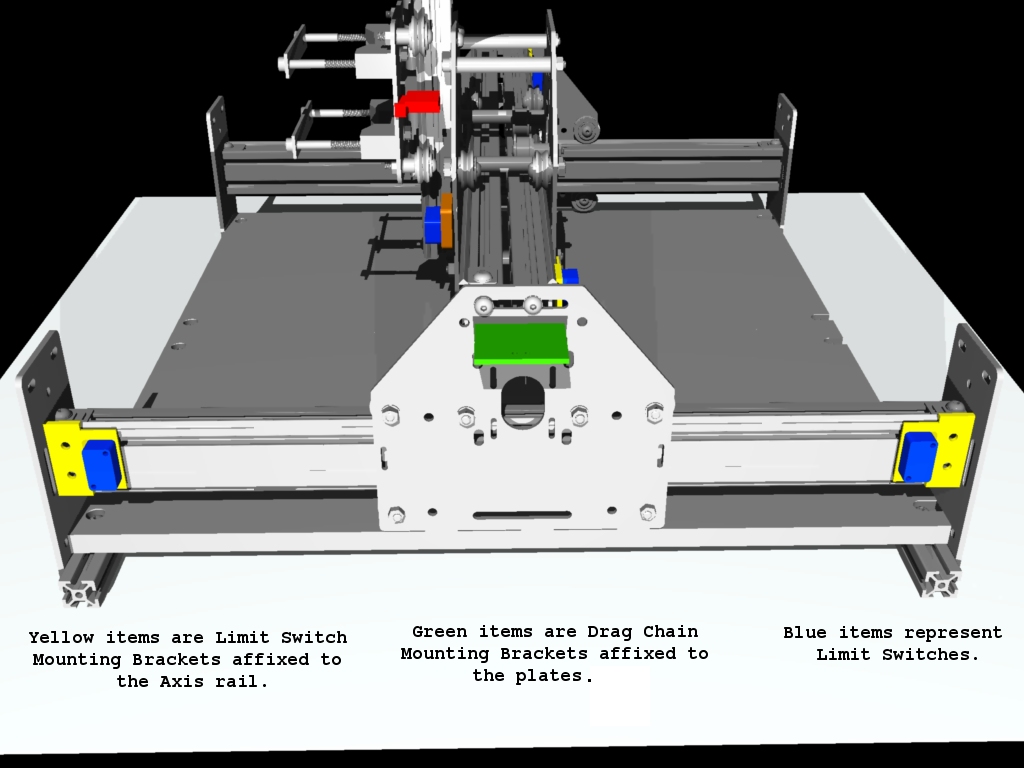

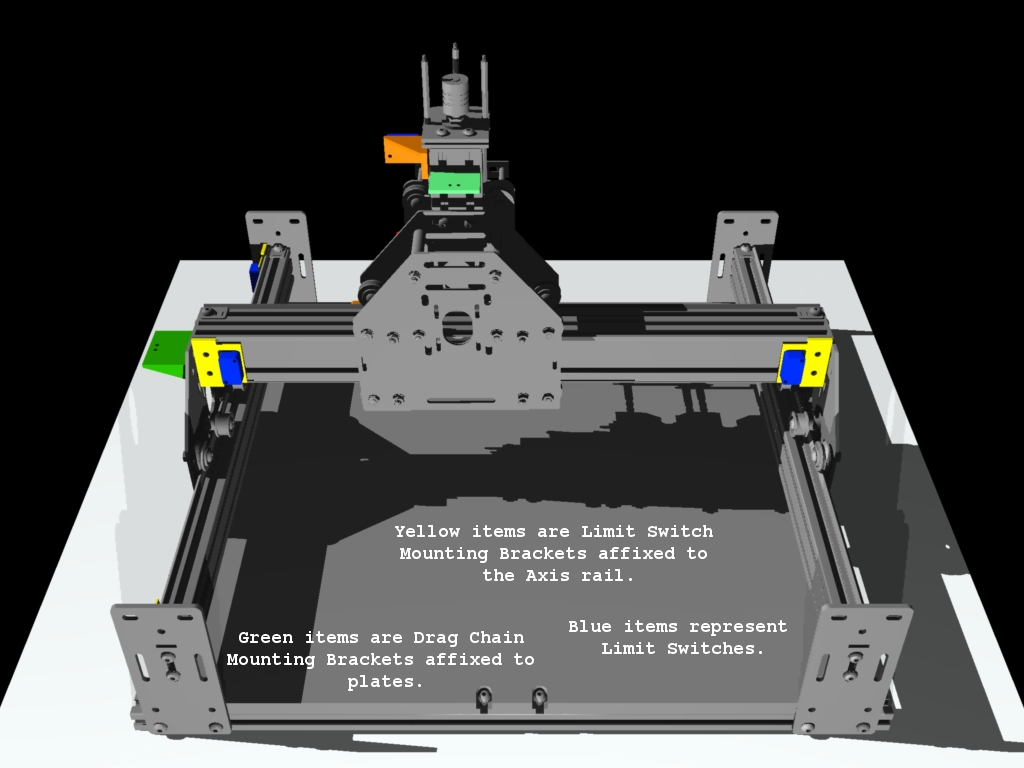

Goal 1: Shapeoko 2 Device Refurbishment

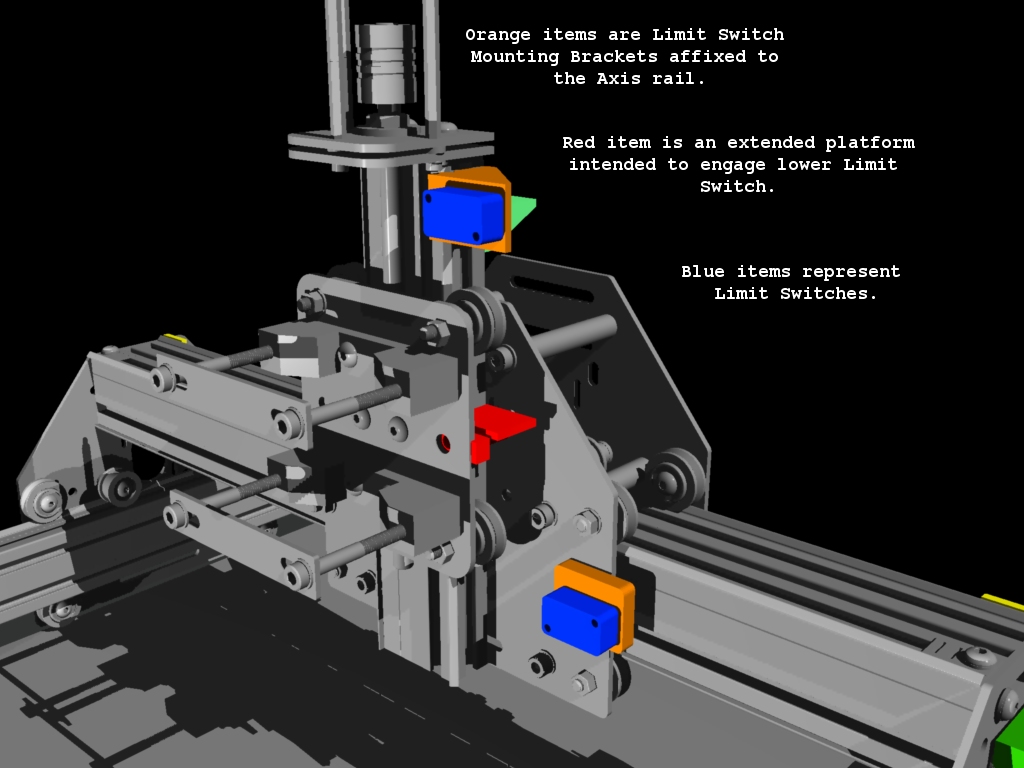

Goal 1: Placement of Custom 3D Printed Parts

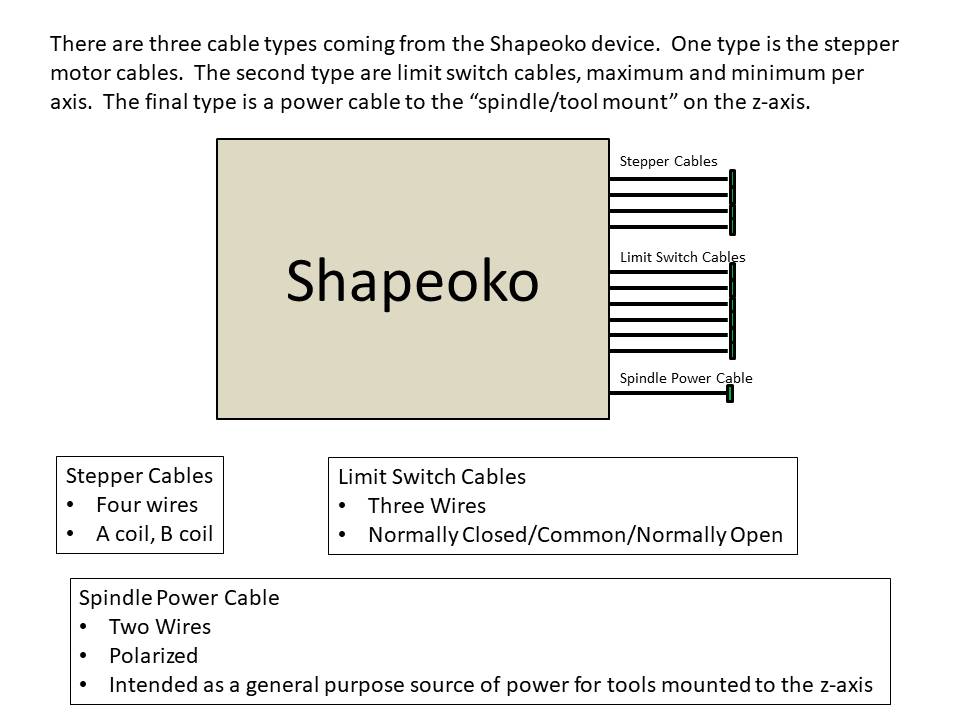

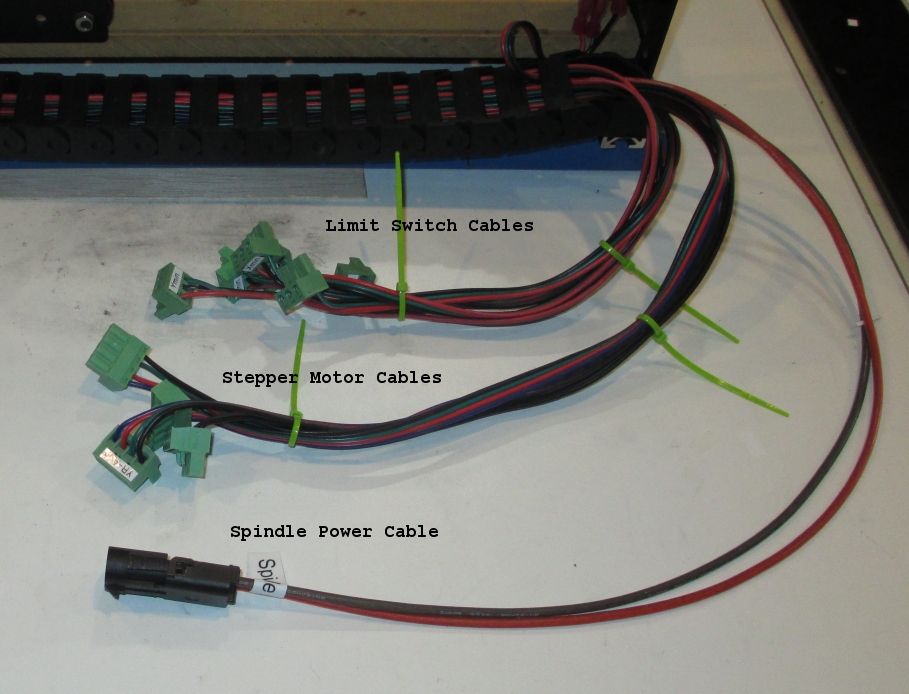

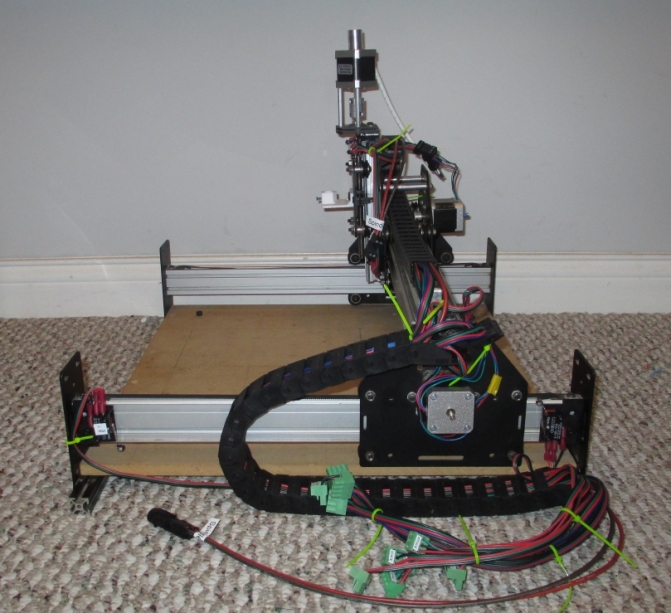

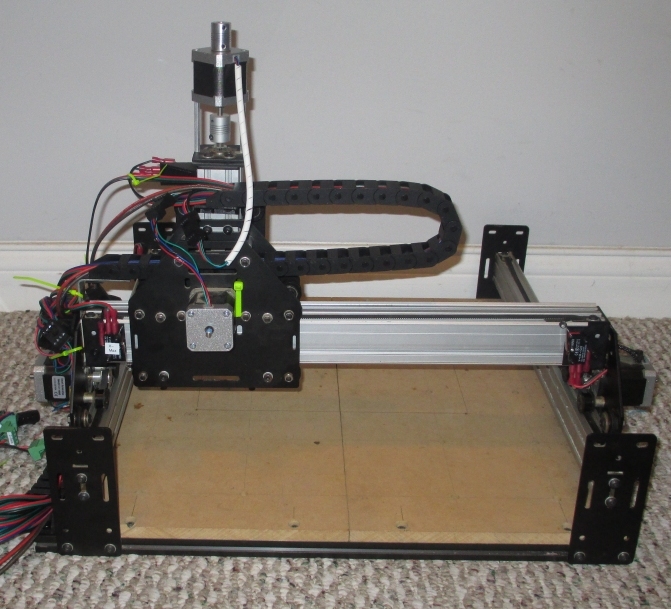

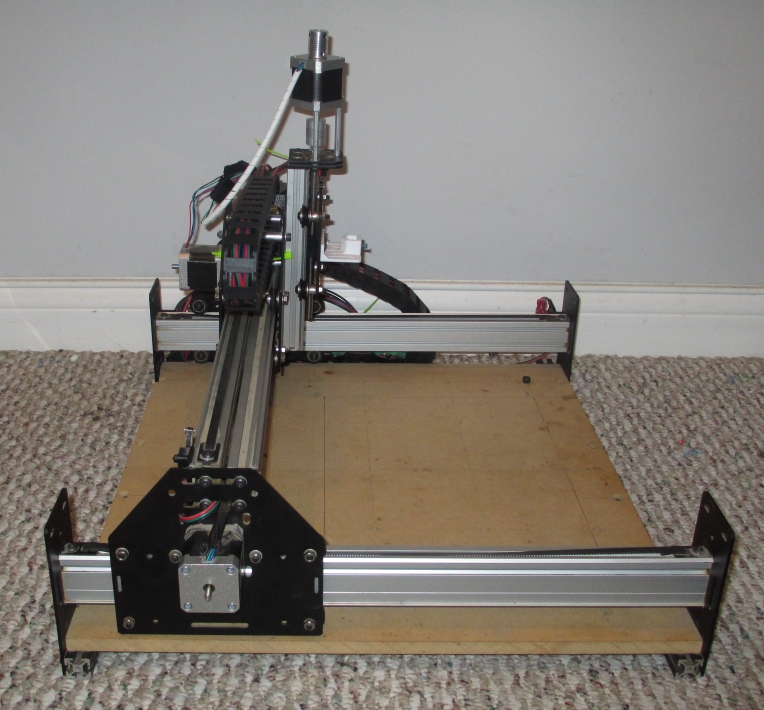

Goal 1: Rewiring

Note: The Spindle Power cable has a modification. The end connector is not common. So, a new connector has be added as a matched pair with screw terminal. The use of screw terminal connectors makes "cutting" of wiring less likely and allows reuse of connectors. The connectors do not require soldering and allow for rewiring without need to "get" new connectors or "solder" lines. A lot of wiring repairs have inline splices that cause later difficulties. The screw terminals would allow entire wiring replacement.

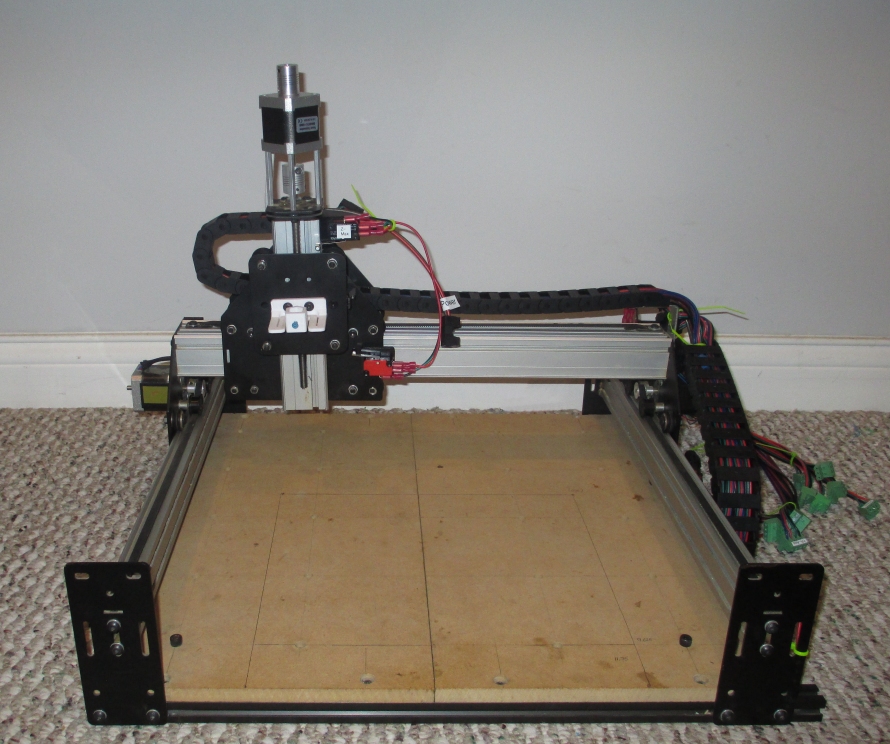

Goal 1: Completion

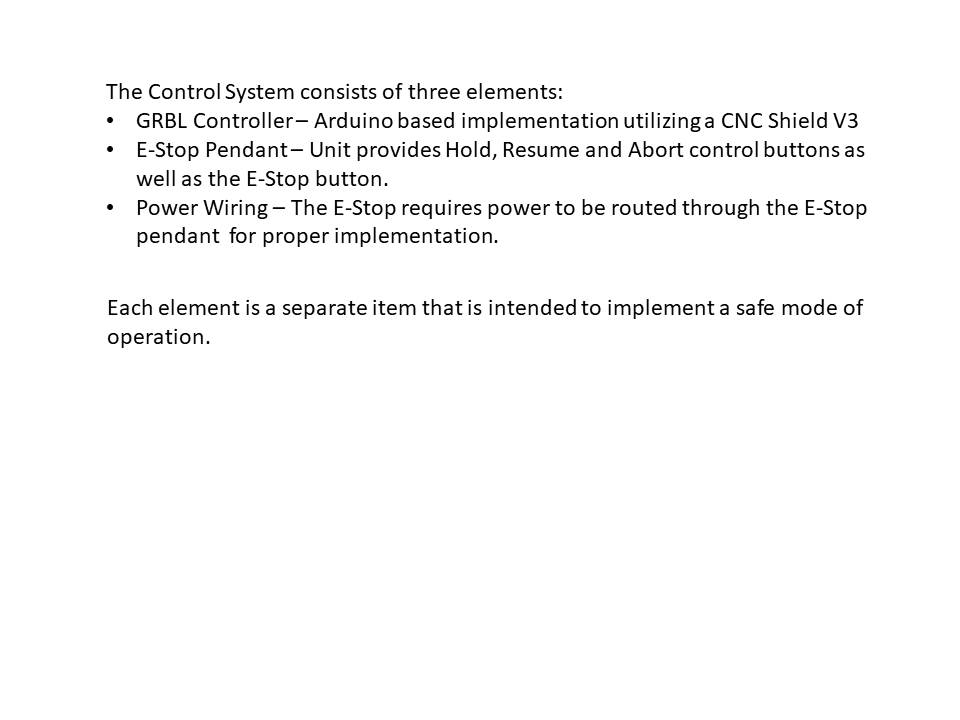

Goal 2: Controller System

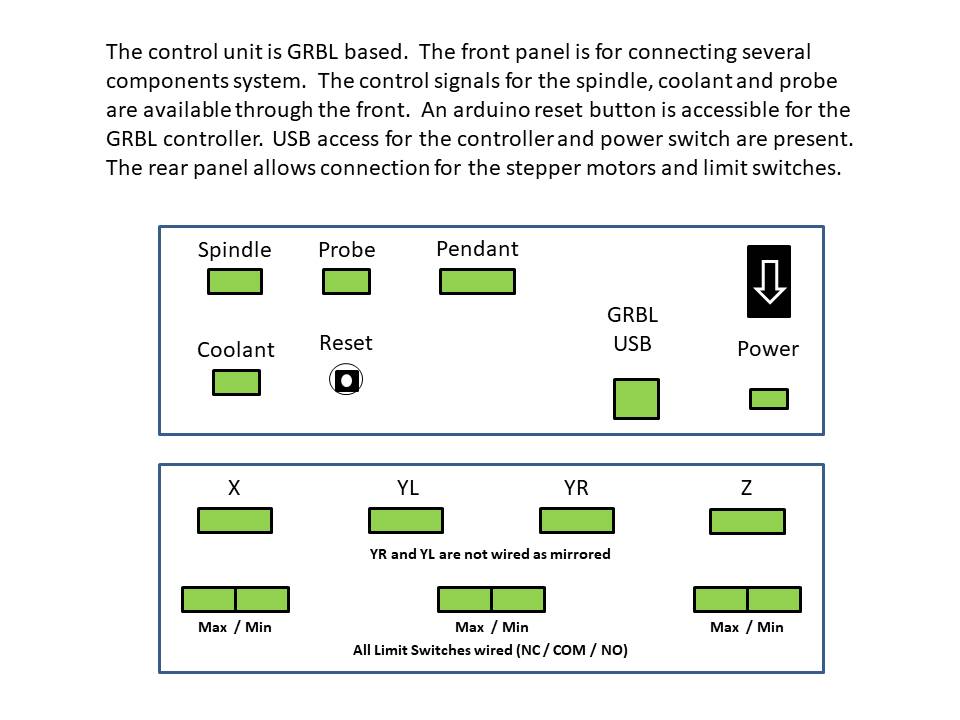

Goal 2: Controller Description

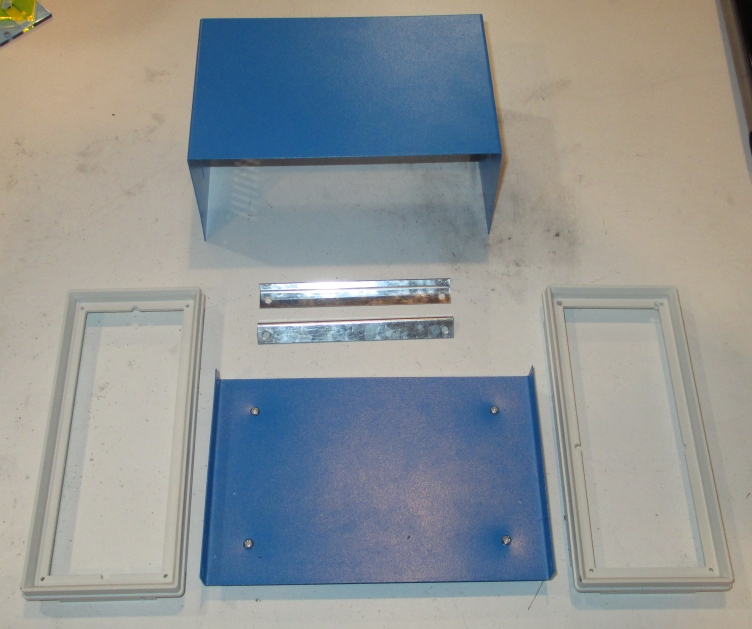

Goal 2: Controller Box

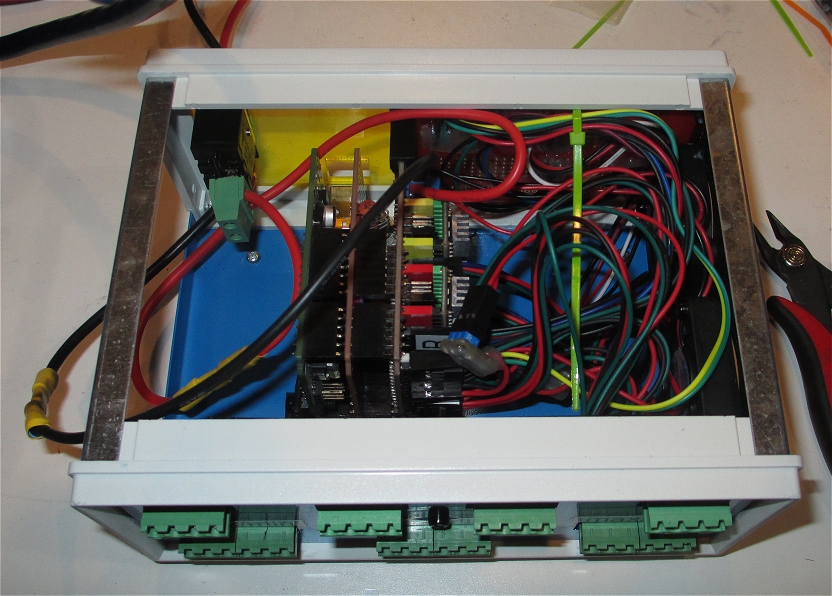

Controller Box Assembled

Controller Box Disassembled

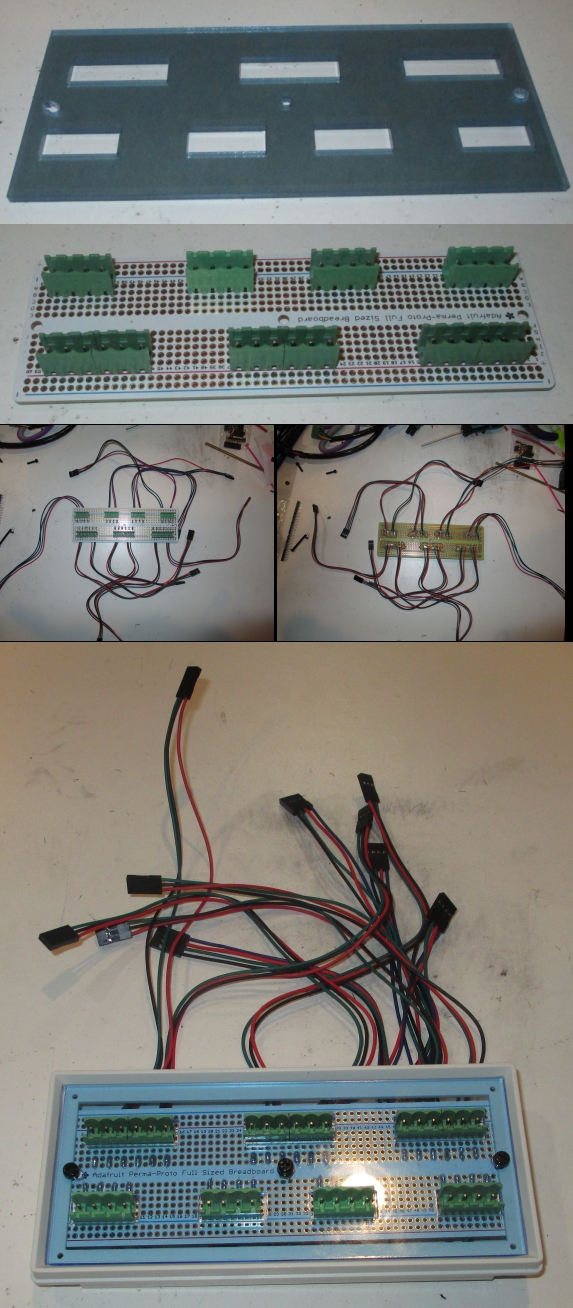

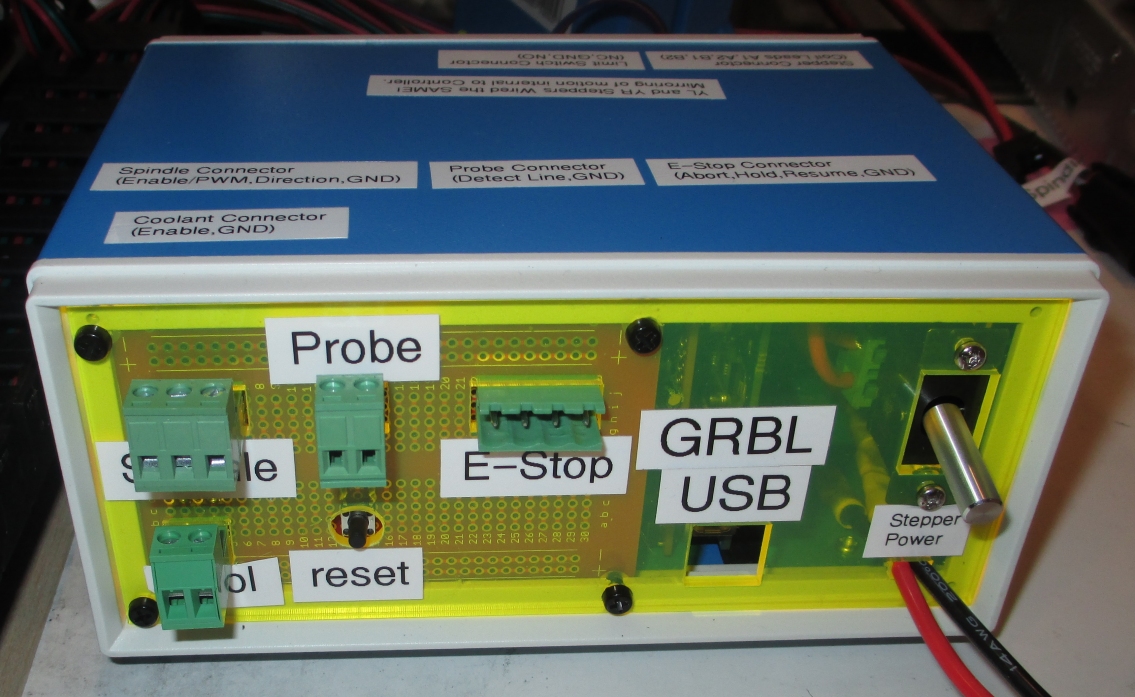

Goal 2: Front Panel Build

Goal 2: Rear Panel Build

Goal 2: Electronics

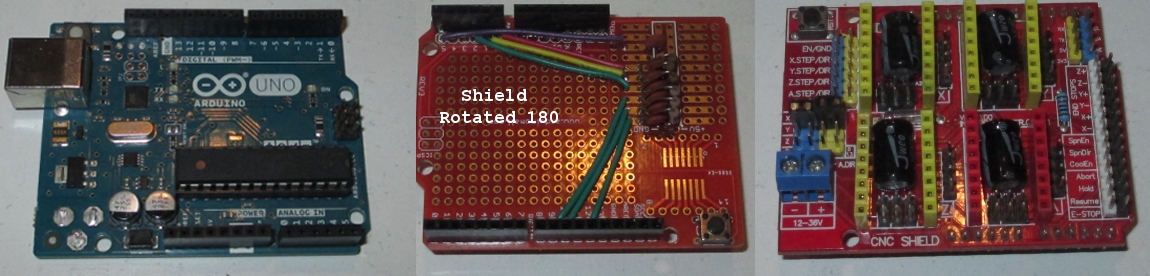

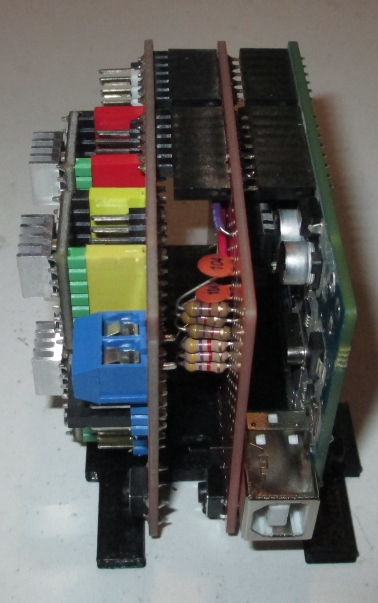

Three Boards - Arduino Uno, Arduino Prototyping Shield, CNC Shield V3.0

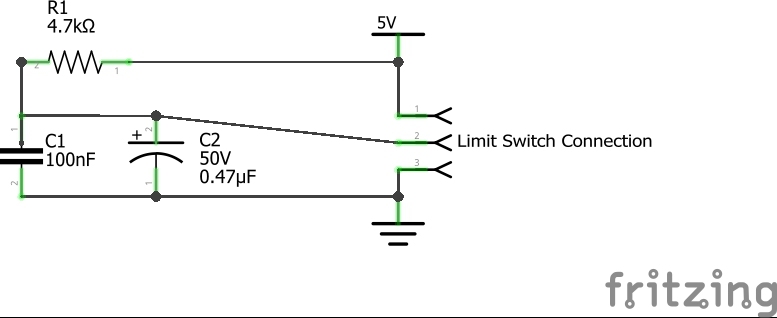

Notes: The Arduino has its power jack removed. The Arduino is powered thru the USB. The circuitry on the Prototyping Shield added noise filtering and debounce protection to the Limit Switch Lines and Control Buttons on the E-Stop pendant. The circuitry in the photo was modified according to the schematic below to improve debounce behavior.

The electronic were assembled in the stack below.

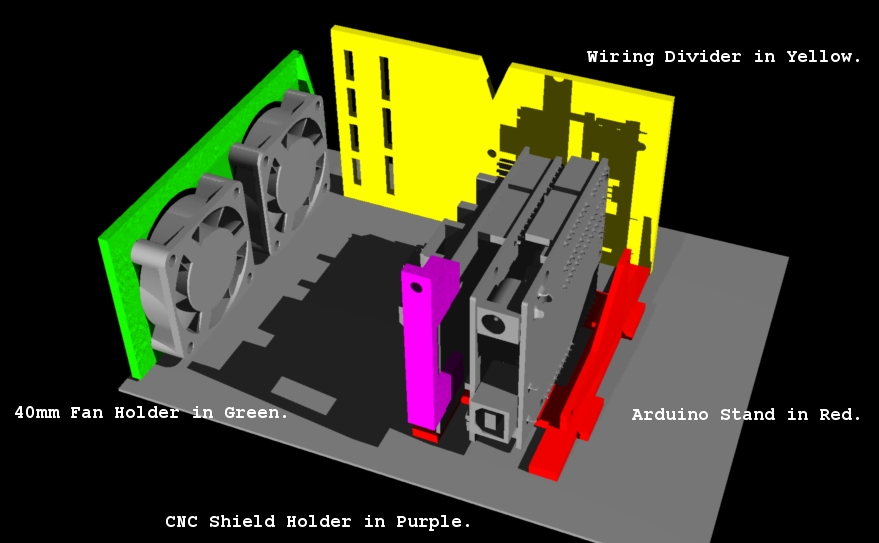

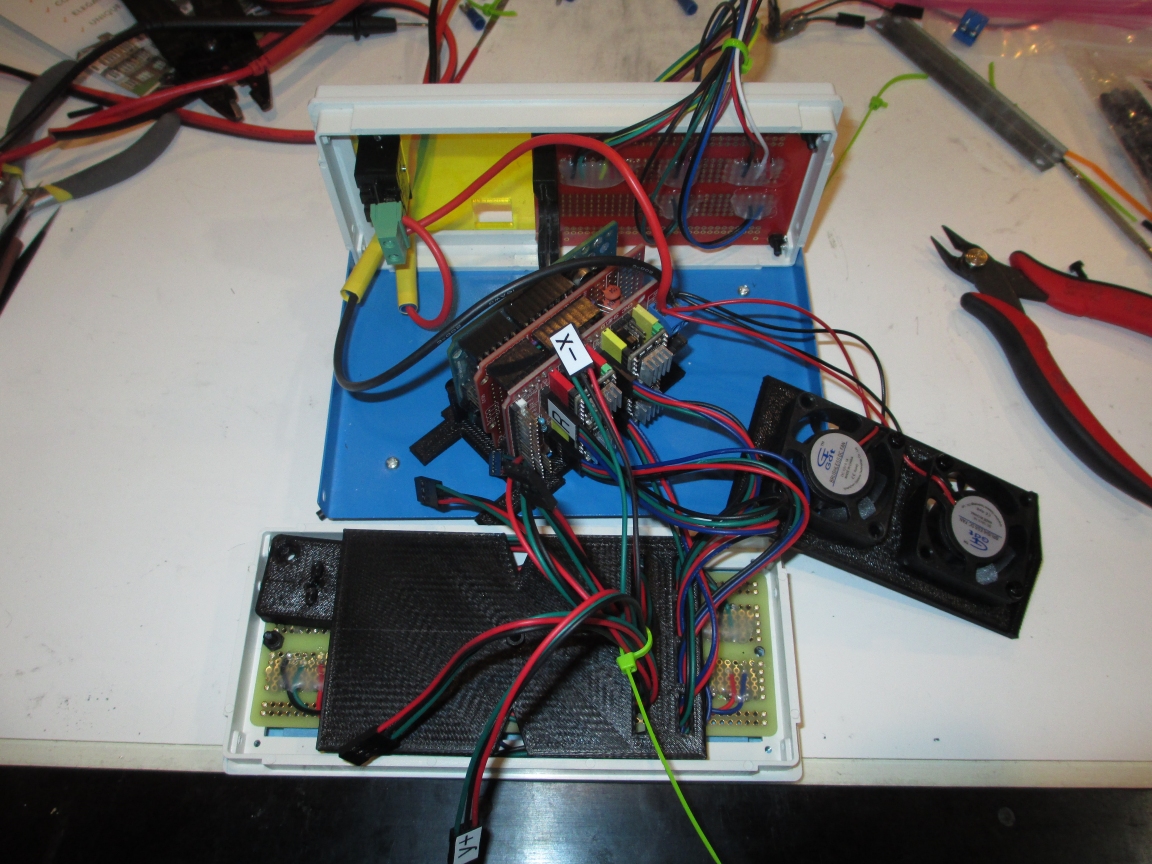

Goal 2: Controller Box Assembly

The electronic, wiring and cooling fans were organized and supported by custom 3D printed parts.

Overall Controller Box Contents

Assembled Controller Box Contents

GRBL Controller Assembled and Labelled

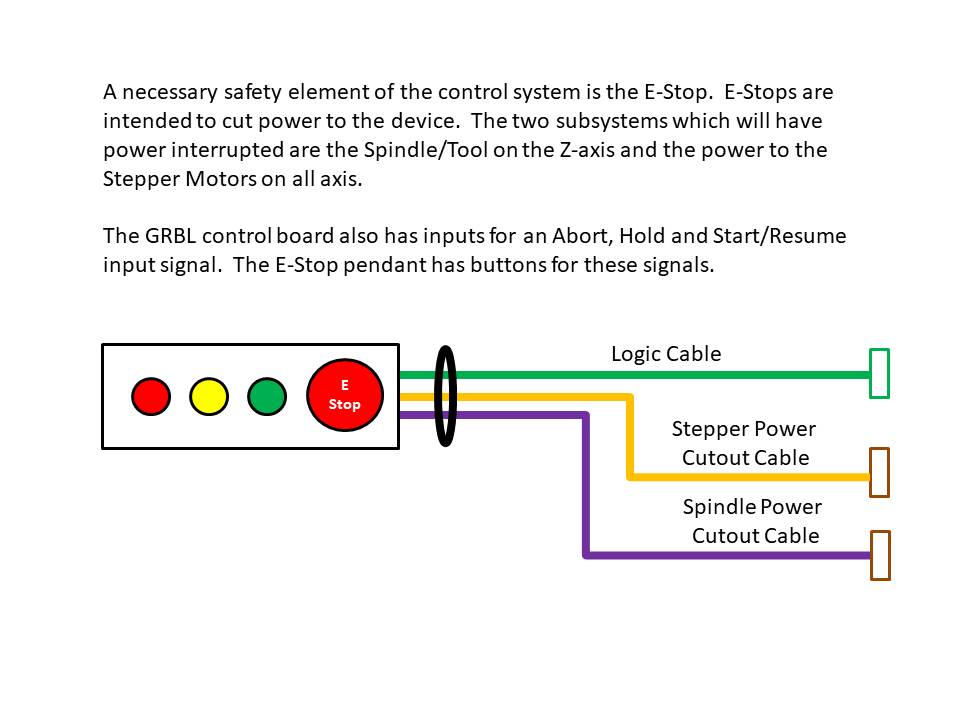

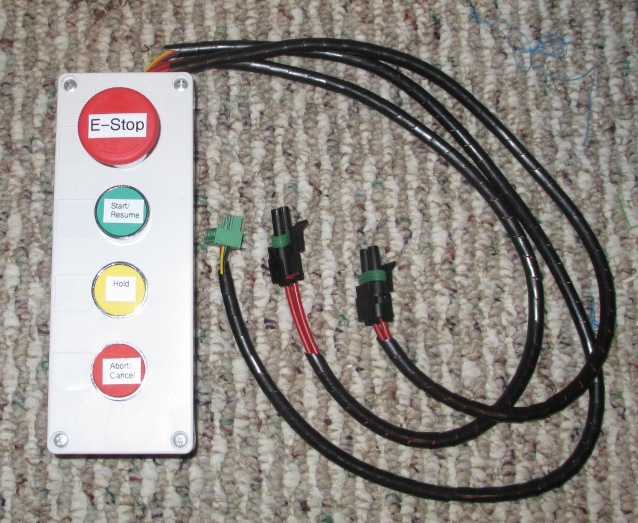

Goal 2: E-Stop pendant

Actual E-Stop pendant

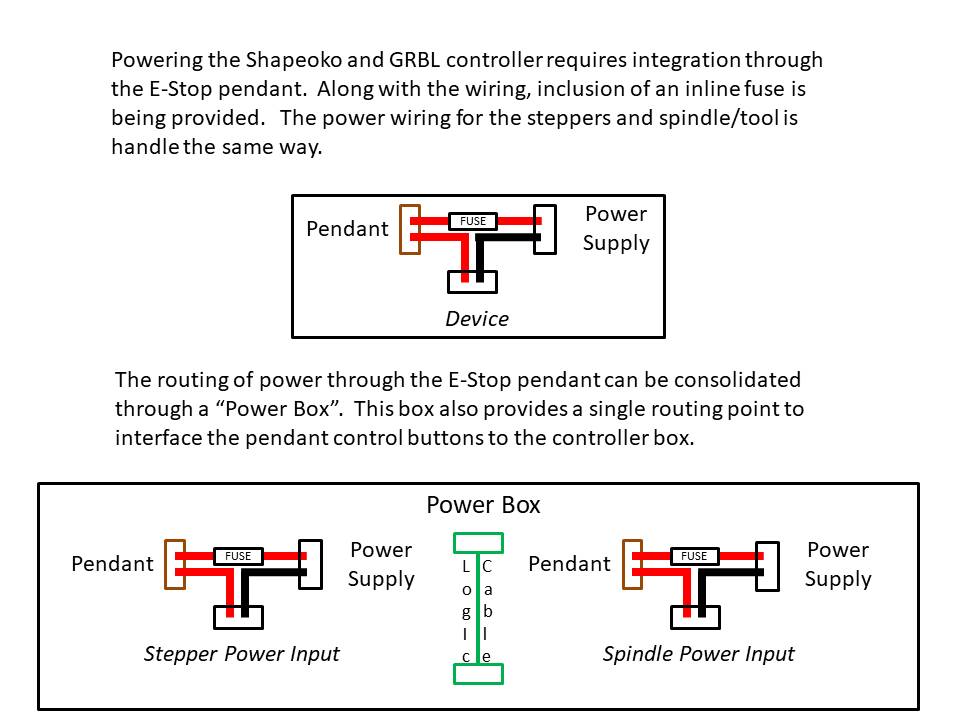

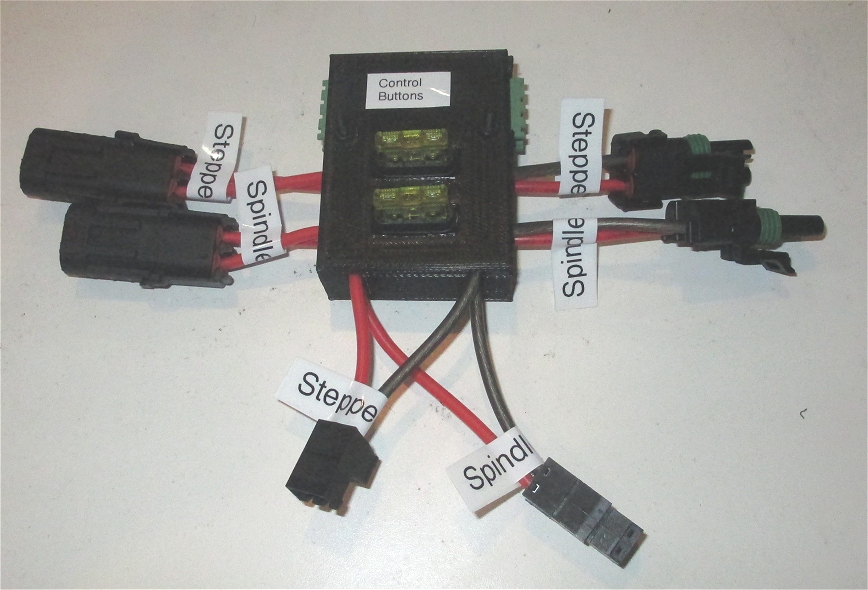

Goal 2: Power Box

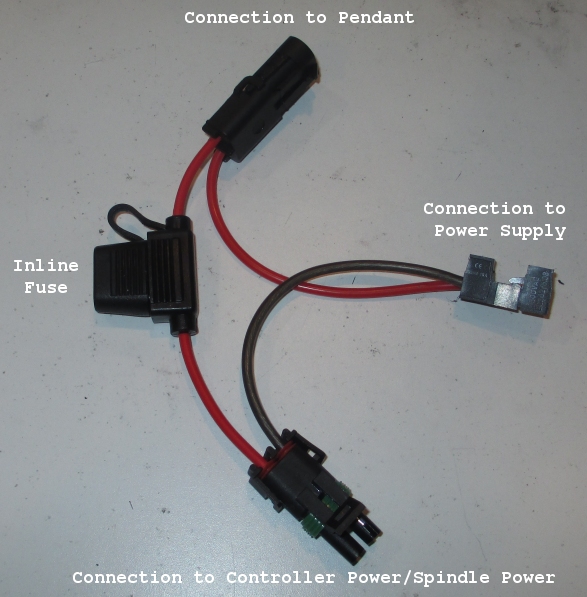

Example of an isolated power wiring harness

Power Box with two power wiring harnesses and control button connector

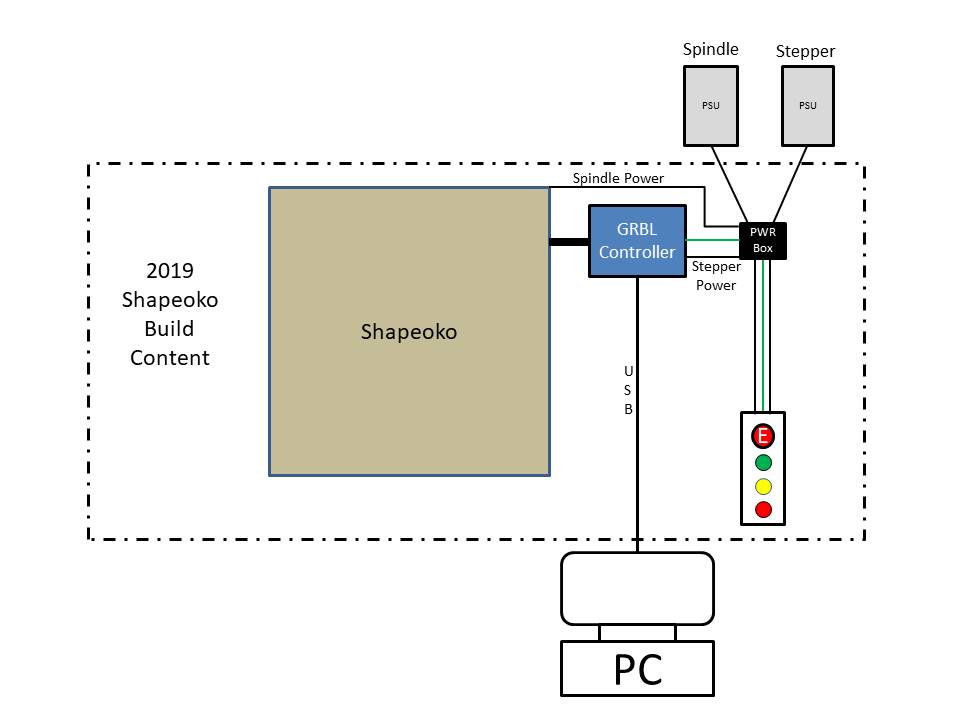

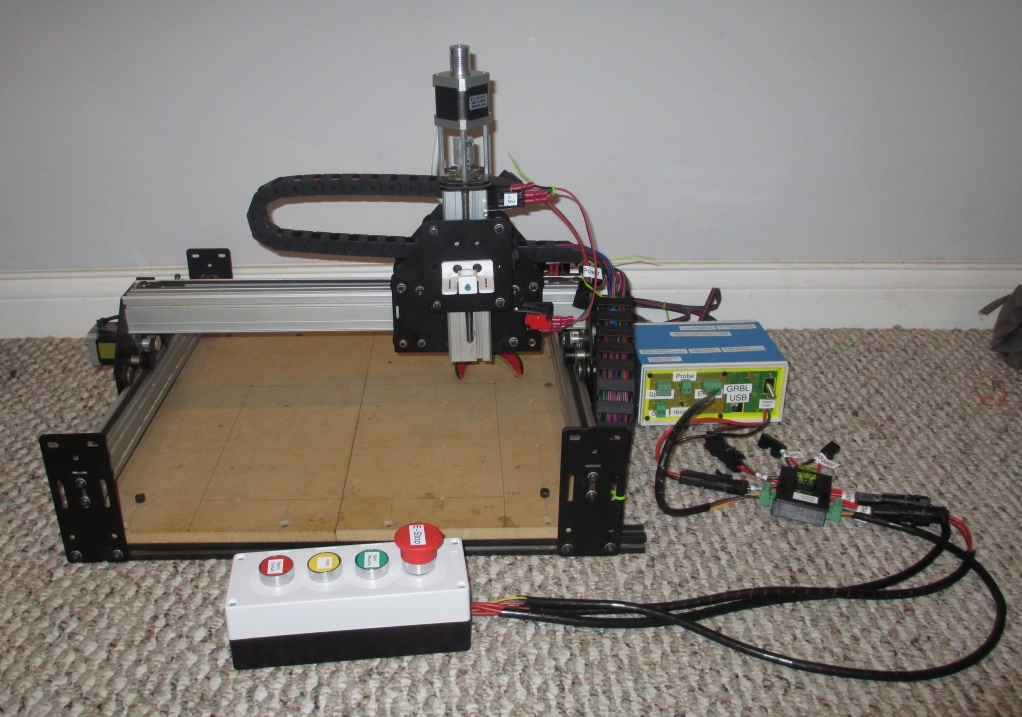

General Layout of Refurbished Shapeoko 2 and GRBL Controller

Actual Layout