LCEM

LASER CUTTER ENABLED MODULE or LVL1 versus The Smoke Monster

Contents

The Genesis

The LVL1 Hackerspace has had the great fortune of receiving a grant to purchase, among other things, a large format laser cutter.

The Problems

But with a laser cutter comes the responsibility of handling the fumes (The Smoke Monster). A simple examination of the cutting bed shows its ilk.

The first method of attack was to vent the beast.

But fumes vented to the outside, still smell funny. And even though LVL1 is located near a place that turns pigs into wonderful breakfast meats, there were a few complaints. LVL1 dutifully upgraded the system with a larger capacity filter and all went well.

But filters are a fussy lot and when they clog, the smoke monster escapes. After much coughing, a new element is added that monitors the air flow through the filter and when reduced or clogged, the laser firing circuit is disabled.

All is now right with the world, unless you are using the laser cutter and the filter trips the flow switch and the laser circuit stops firing the laser. The cause of laser-interruptus is not always apparent. Sometimes the settings on the machine can prevent the laser from firing during etching operations. The top closed switch could stop the firing. Both cases result in the laser cutter gracefully moving across your material while nothing is vaporized. So how do you know its the filter flow switch and not something else?

A Laser Cutter Enabled Module.

The requirements were simple.

1. Show a light when the laser circuit is enabled or conversely when disabled.

This makes sense. Then someone asked about what if the indicator system is not working. A lack of light could mean what it is supposed to mean or the indicator is not working.

2. Show a light in either case. Green for enabled and Red for disabled. No light means the indicator circuit is not working. A bi-color LED would solve the problem.

Problem solved. Until someone asked about color blindness and knowing if the LED is RED or Green. This was an excellent point.

3. Two LEDs are used. One Green with appropriate label of "Enabled" and one Red with appropriate label of "Disabled".

The crowd then remarked about statistics keeping, quantitative measures and raspberry pi. These wonderful suggestions were immediately suppressed and work on the indicator began.

All On Paper.

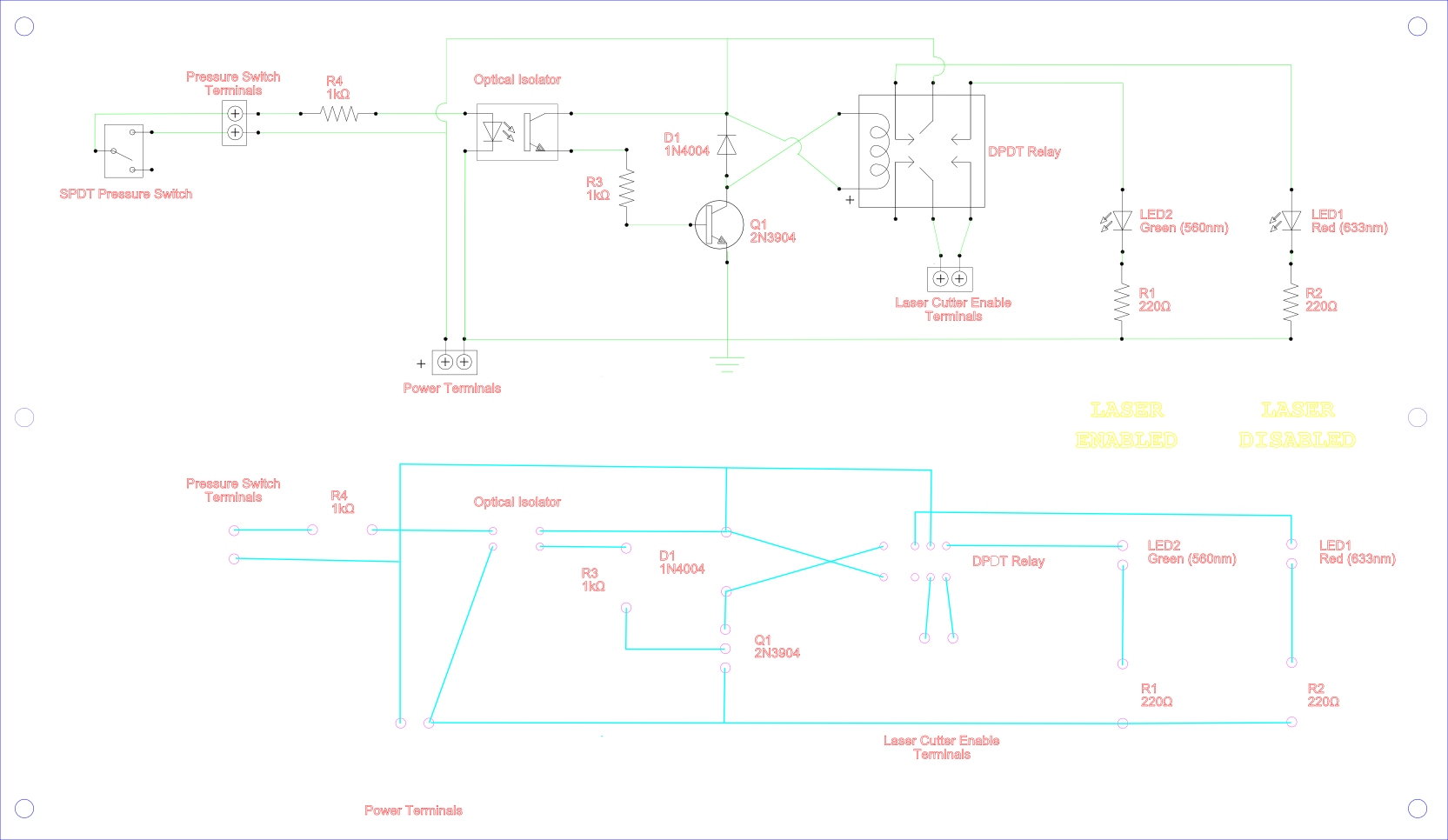

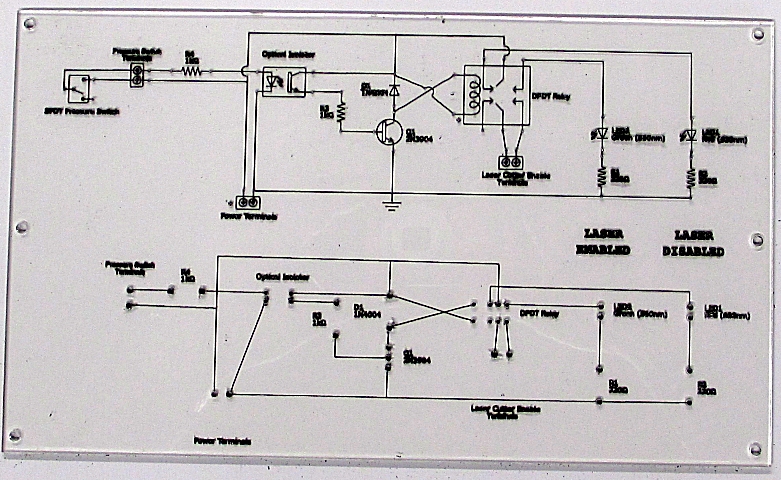

The preliminary design began. These documents were produced.

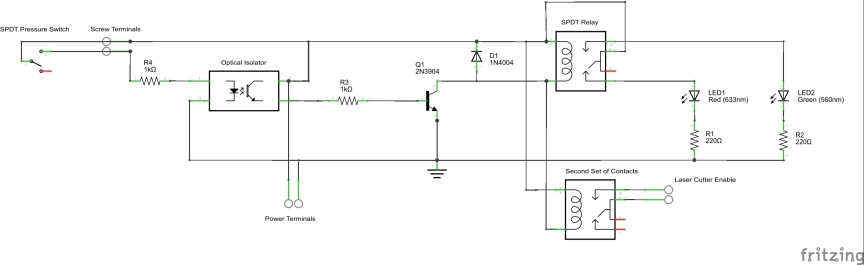

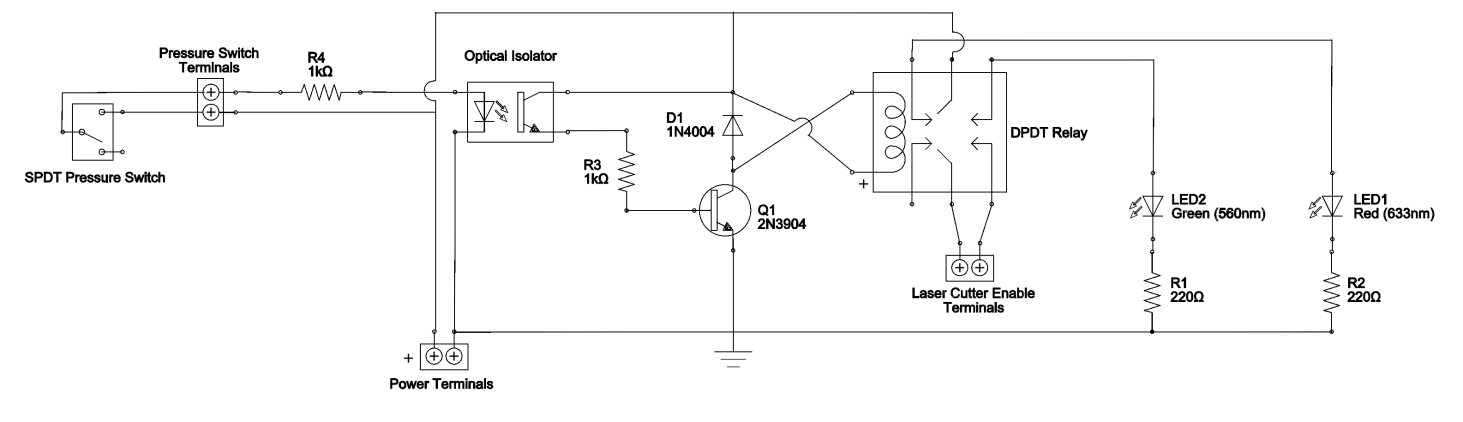

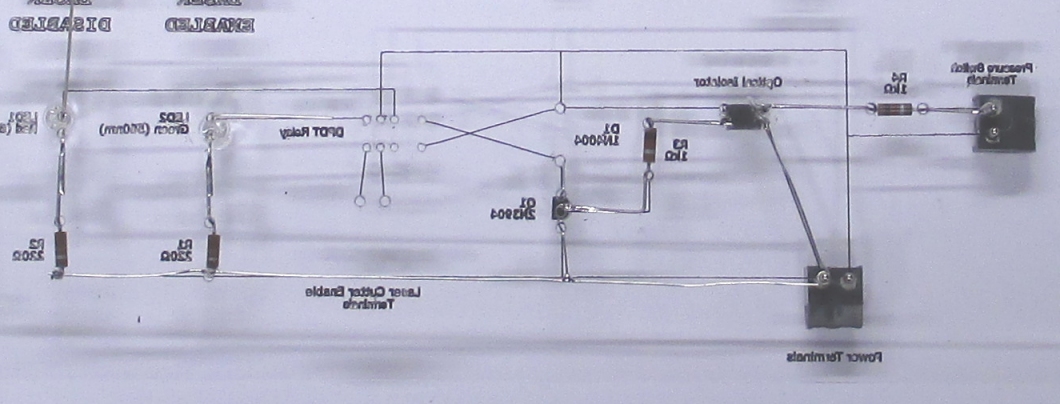

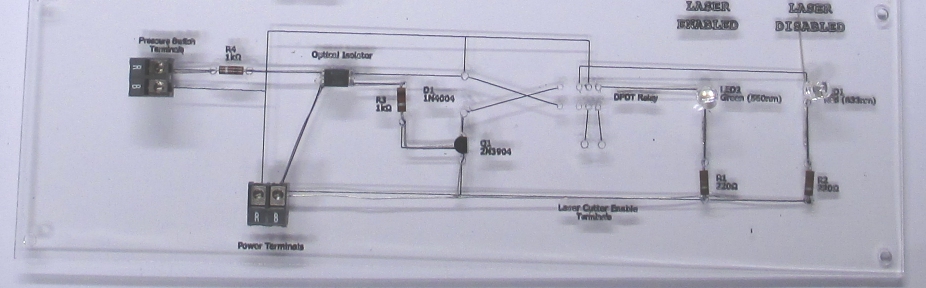

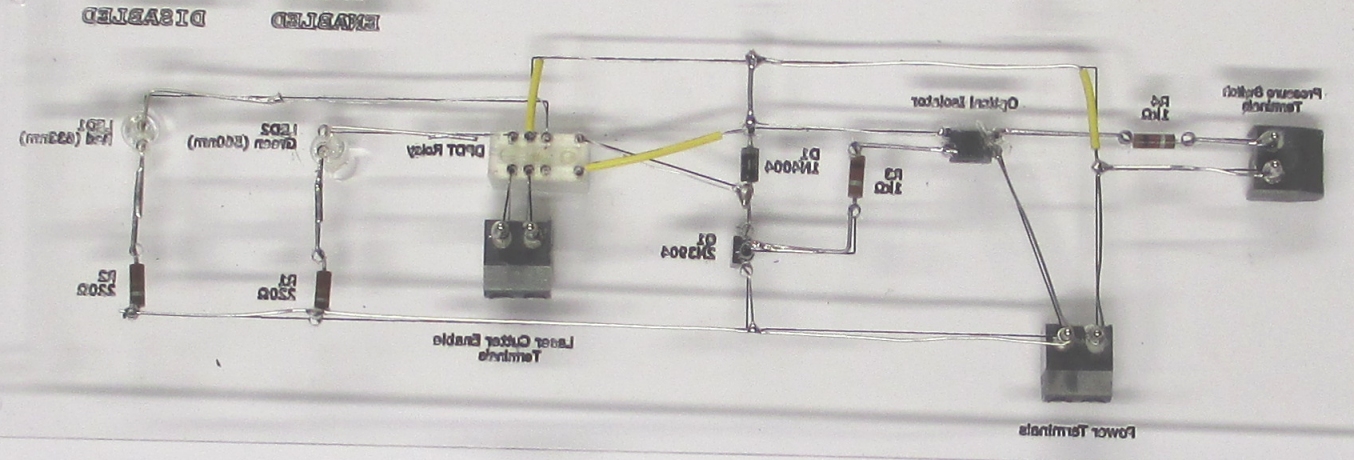

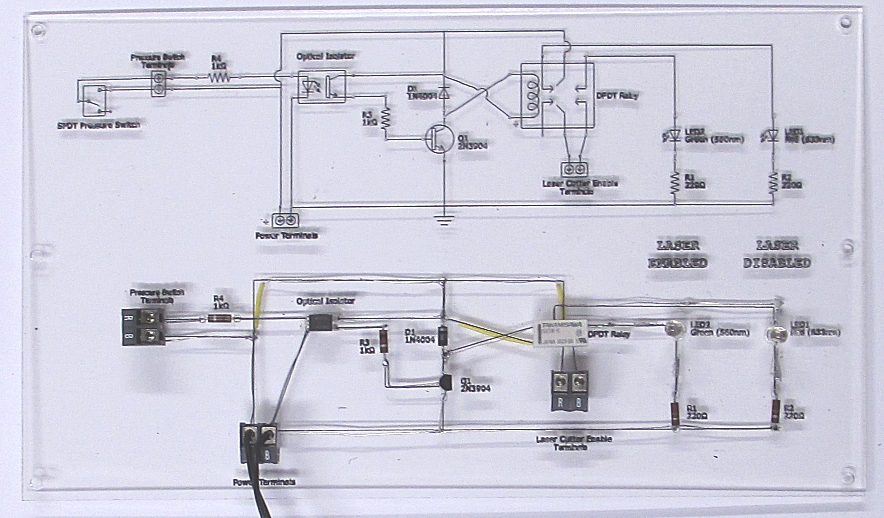

The design is simple. The filter flow switch is connected to power and an optical coupler. When the flow is adequate, the optical coupler is activated with a small voltage effectively using the flow switch as a simple off-on switch for its embedded LED. The other side of the optical coupler is used to switch on a relay. When the relay is inactive, power is supplied to a Red LED. When the relay is active, power is supplied to a Green LED instead. Green LED lit means laser circuit enabled while Red LED lit means laser circuit is disabled. If no LEDs are lit then the indication system is not working.

Madness Indicator

Use of an optical coupler is a bit over kill. LVL1 Hackerspace never criticizes the overkill.

In Real Life

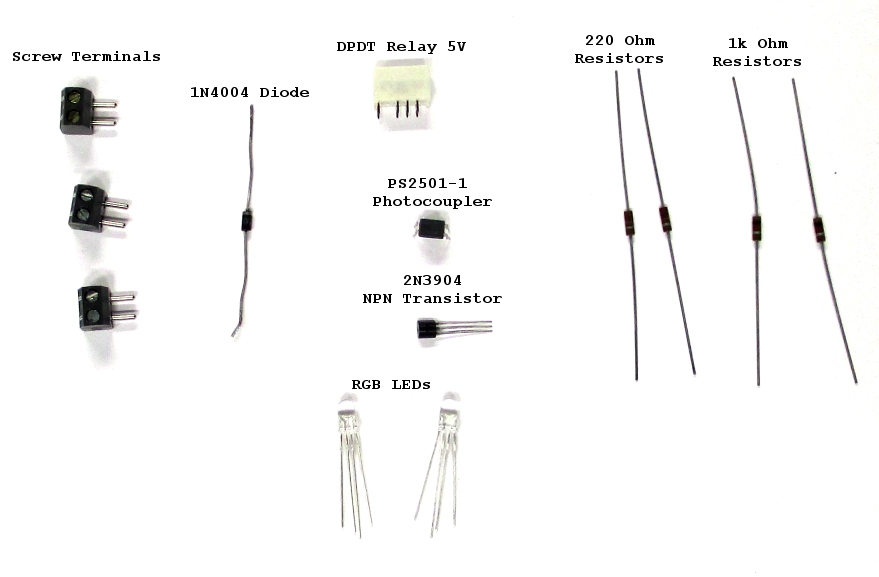

The preliminary design was sound. It was time to gather components. Real life meant that a single DPDT relay could be used instead of two SPDT relays with tied together coils. Real relays can also have polarized coil inputs to accommodate a number of real world issues. LEDs, one Green and one Red should be the easiest things to come by. But the easiest things to come by are often not readily at hand when going through a hackerspace component junk drawer. That is not to say that we didn't find a Green and a Red LED, but the ones found did not aesthetically match one another. Then the issue of brightness came into the discussion. The solution was within the madness quotient of the builders and two bright RGB LEDs were selected. The selection of the back-emf diode was based upon a 1N4004 being in the junk drawer. Quick resistor values were chosen and pulled from junk drawer.

Madness Indicator

Some may notice the old/ancient resistors being used. These were part of a donation from a member, now deceased, with an electrical engineering degree older then almost all of LVL1's members. Ron, you are missed.

Simple Presentation

The obvious black RadioShack project box with two LEDs on top design was discarded immediately. LVL1 is about building distinctive things when something less is required. The design chosen would be too much work with multiple intents. The design would have its schematic visible for those curious to know how it worked. The design would have its PCB visible to show how the PCB and schematic are not physically laid out the same. Laser cut acrylic would be used since this is a laser cutter project. And because the author likes dry erase boards, a dry erase marker must have some fundamental part in the build.

Here is what was decided.

Above is the file to be used to create the PCB/Mounting Plate/Educational Schematic/Acrylic thing.

Madness Indicator

All of the above.

Cutting Acrylic

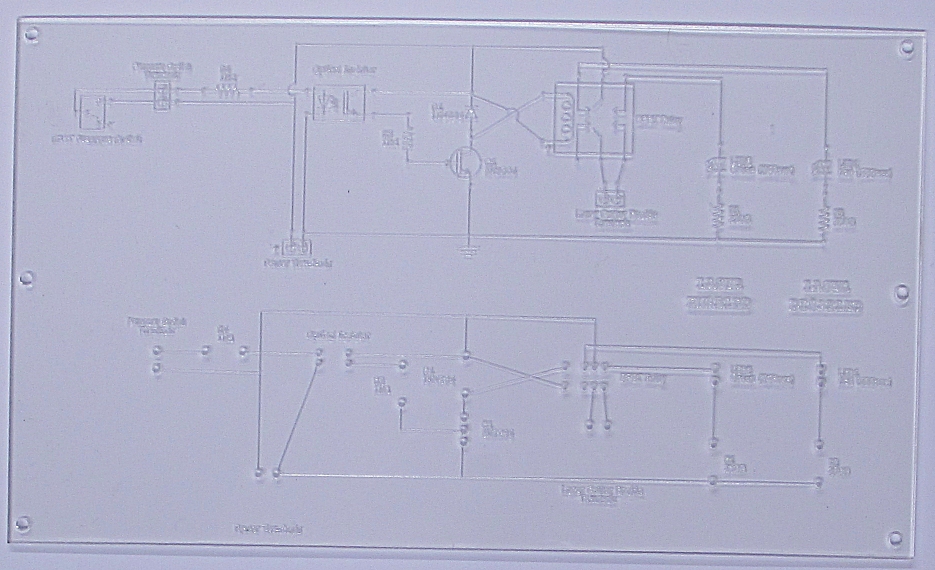

First thing was to cut the acrylic plate.

That was easy but the plate is not very readable. So, the dry erase marker method was utilized to bring out the line art.

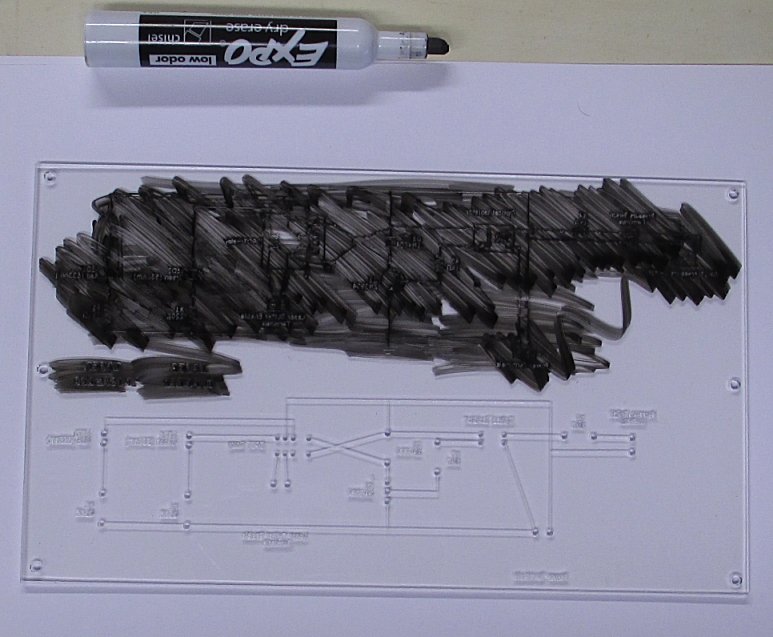

Marker smeared on.

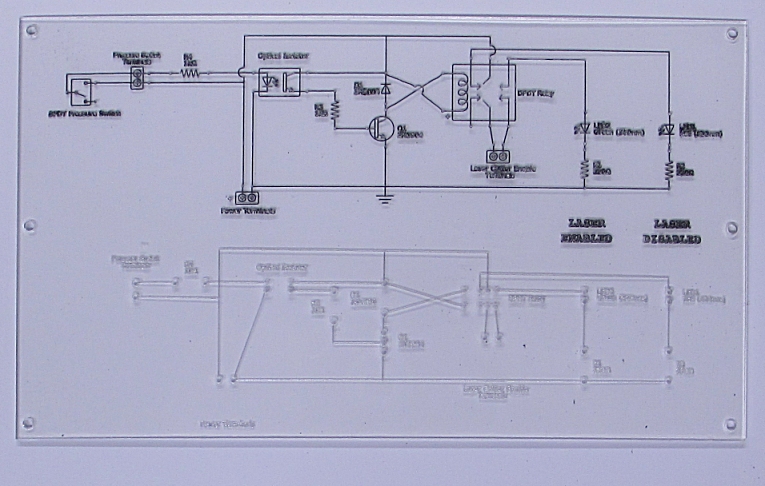

Marker wiped off.

Dry Erasing completed.

Of course, the cutting and etching is done mirrored so that the side with marker deposits is not exposed outward. Knowing to mirror this is obvious, however that doesn't mean LVL1 doesn't have another plate just like this with the etching on the wrong side.

Madness Indicator

Several images in this write up have had adjustments made in size and brightness/contrast. The image above has a curious image of the photographer standing over the plate taking its picture.

Applying Parts

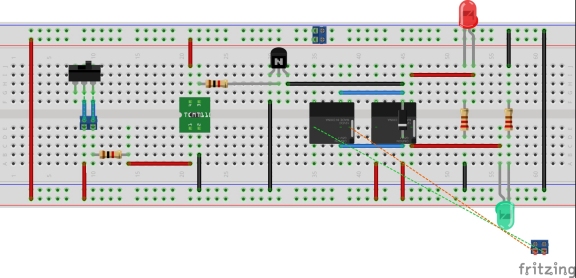

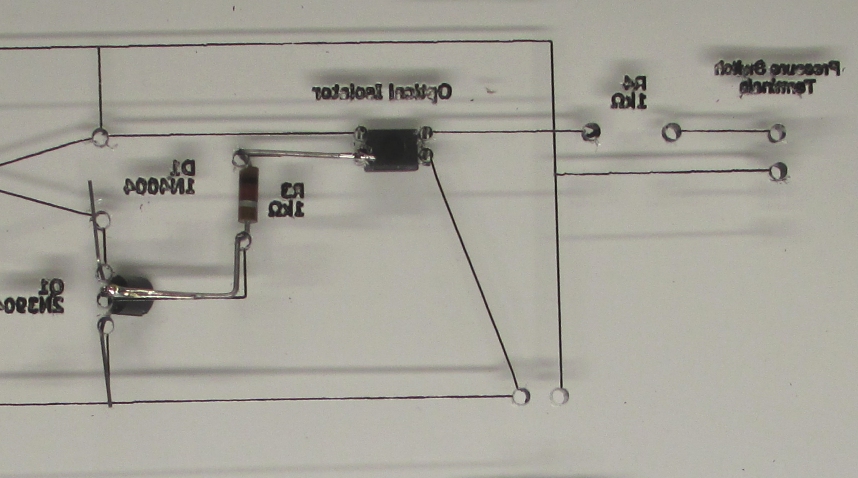

First the components were prepped for installation by placement on the PCB/Mounting Plate/Educational Schematic/Acrylic thing.

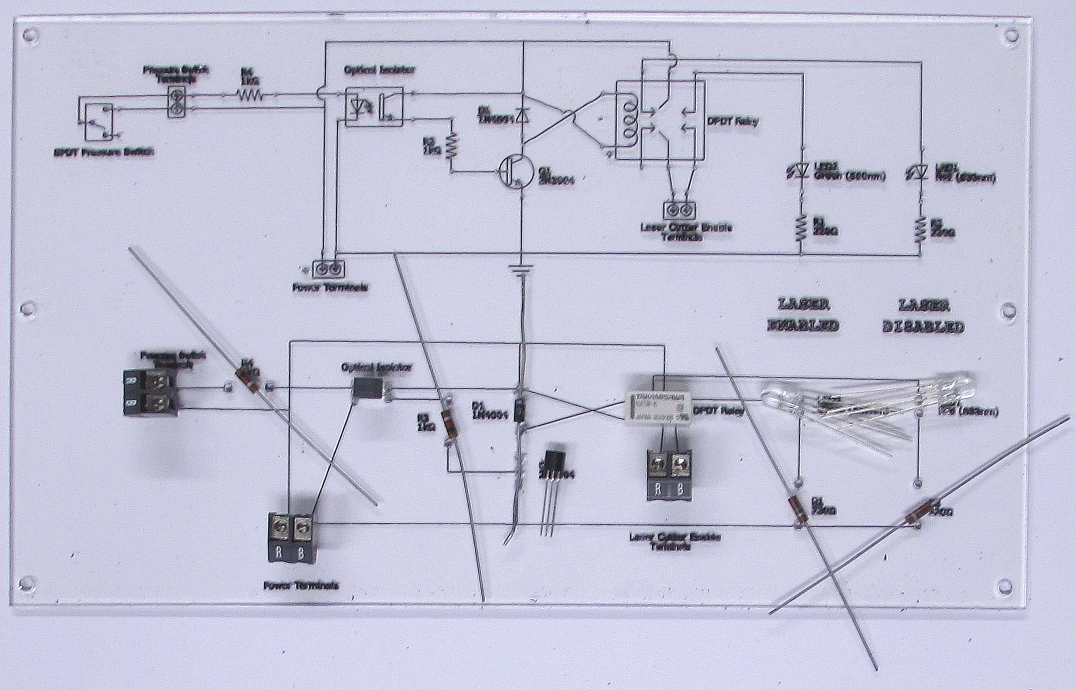

Three components required addition preparation. Two of the components were the RGB LEDs. These components had some leads eliminated, effectively making them bright Green or Red LEDs.

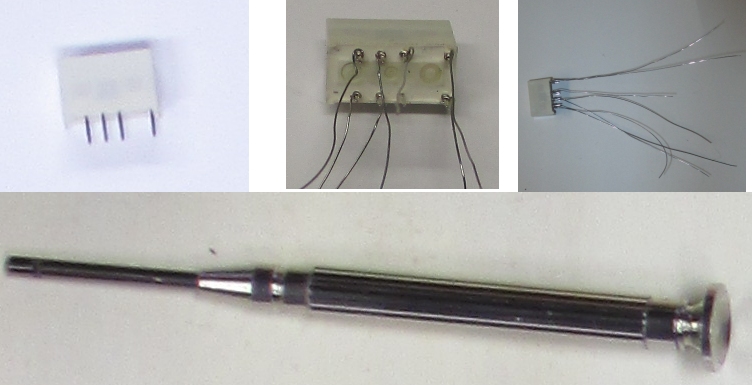

The third component was the relay. The small relay is designed for PCB mounting, but this PCB/Mounting Plate/Educational Schematic/Acrylic thing would not have solder pads. Since component leads would need to be bent and orientated to allow soldering, component leads needed to be added. The chosen way was wire wrap to attach the lead extensions. Why? Because the old ways are the best ways.

Solder Time

Madness Indicator

Yes, the LEDs were soldered in backwards and had to be turned around.

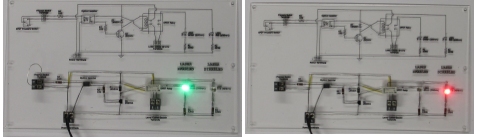

A Test is Needed.

Here it is.

Madness Indicator

Testing is for the infirm.

Final Polish.

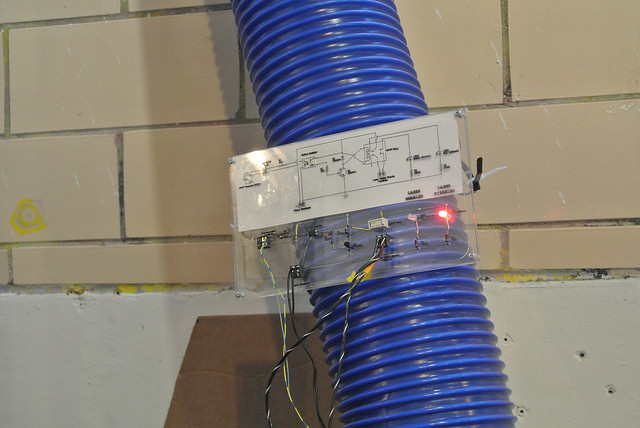

With the device assembled and tested, time to attach. Now there is one issue. The backside of the board has the wiring exposed. The device will likely not be placed in a climate controlled, contact eliminated environment. So, the underside must be protected. The answer for the Laser Cutter Enable Module is to cut more acrylic. A single sheet is cut with an open center, like a gasket. Another sheet s cut with holes for attaching it, sandwich style to the other two pieces. This forms an enclosure. With center side holes ready for mounting rigging, all is set for installation.

Madness Indicator

Just look at what has been done for such a simple project.

Installation.

This is where it all ends.