Shapeoko Repair Madness 2016: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

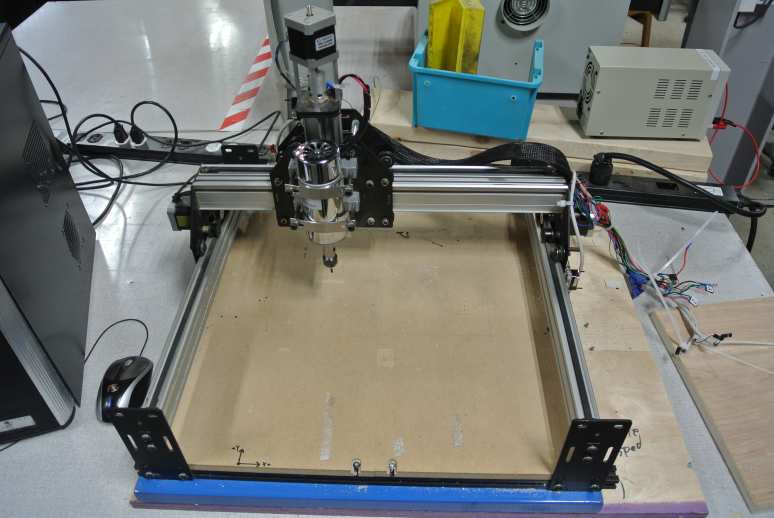

= Survey the Field of Carnage = | |||

Death of the Shapeoko is just the beginning. | Death of the Shapeoko is just the beginning. | ||

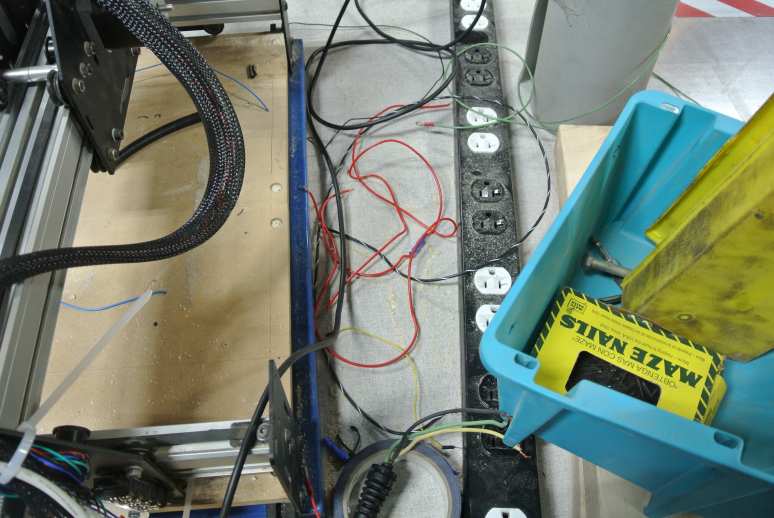

[[File:JACSRP-01.jpg]] | [[File:JACSRP-01.jpg]] | ||

| Line 56: | Line 56: | ||

[[File:JACSRP-17.jpg]] | [[File:JACSRP-17.jpg]] | ||

= Preliminary List of Needs = | |||

== Hardware == | |||

* Cables need to be labeled | |||

* Cables need to be consistent gage and type | |||

* Connectors need to be keyed (so they only fit together one way) and standardized | |||

* Cable routing and securing needs to be redone | |||

** If wire ties are used, they need to be trimmed | |||

* Limit switches need to be securely mounted and wired | |||

* Mounting hardware for table is missing a nut | |||

* Attach spindle to keyed connector | |||

* Control boards need to be tested | |||

* Stepper motors need to be tested | |||

* Determine heat sink and cooling fan needs for control boards | |||

* Determine whether control board interfaces with spindle | |||

* Research alternatives for controllers and connectors | |||

* Research alternatives for table materials & mounting | |||

== Software == | |||

Note: This section will be expanded when hardware issues are fixed. | |||

* Determine whether min/max limits are stored | |||

* Determine optimum software versions and document all settings | |||

Revision as of 22:27, 28 June 2016

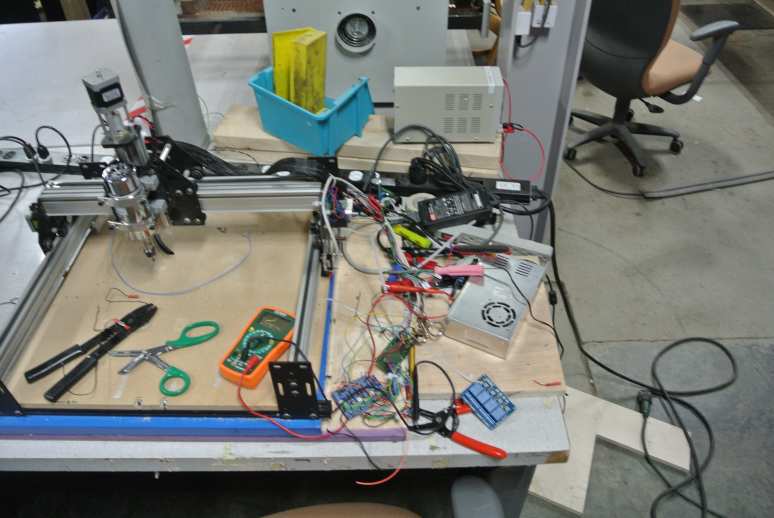

Survey the Field of Carnage

Death of the Shapeoko is just the beginning.

Tool Extraction

But What About Debris

The Debris Found

Debris of Value

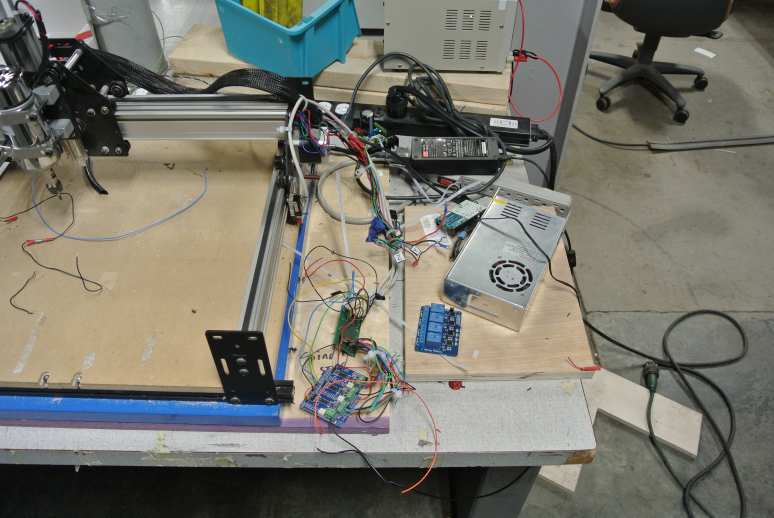

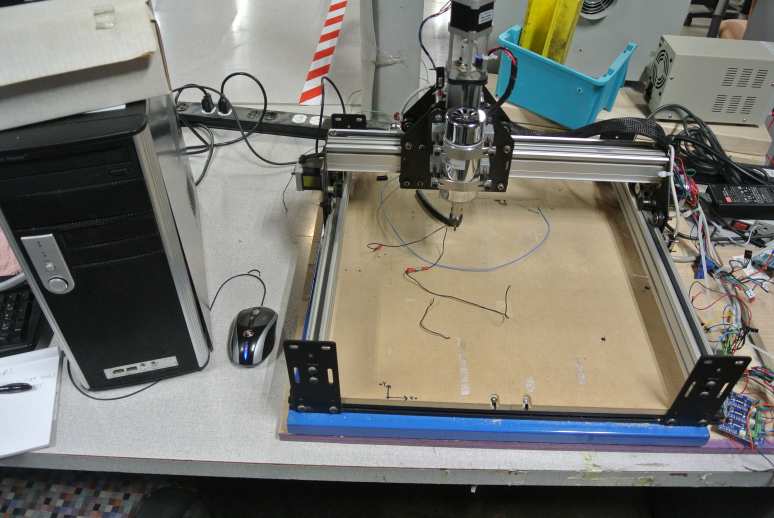

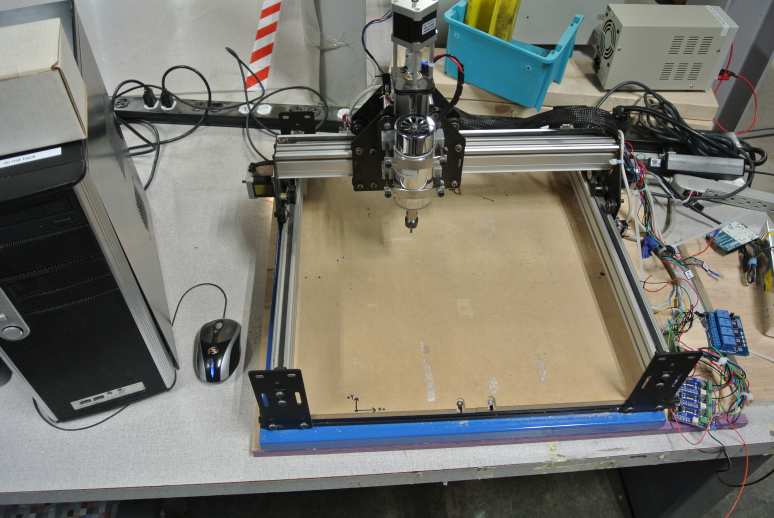

What Remains is the Shapeoko

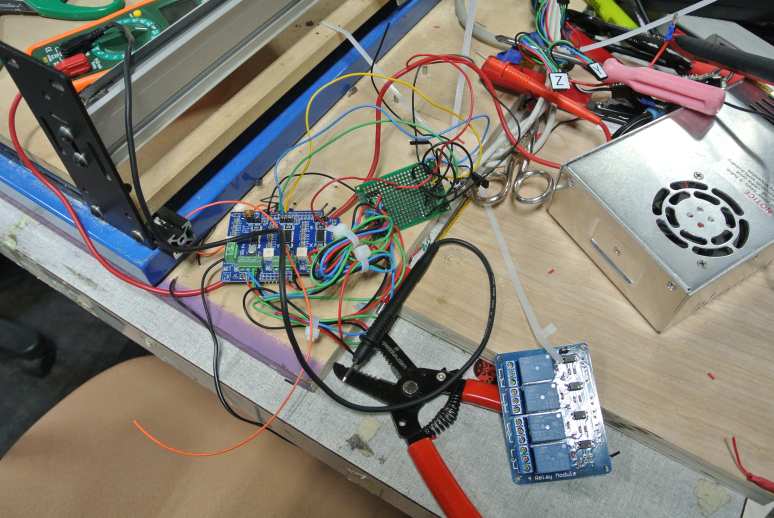

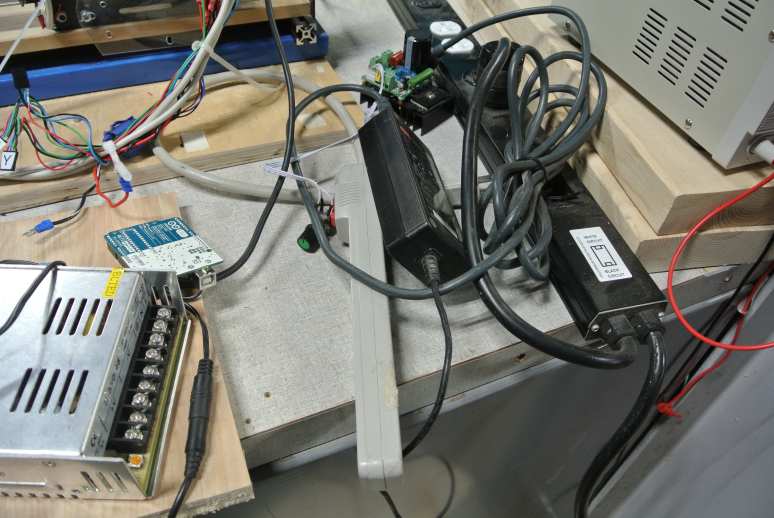

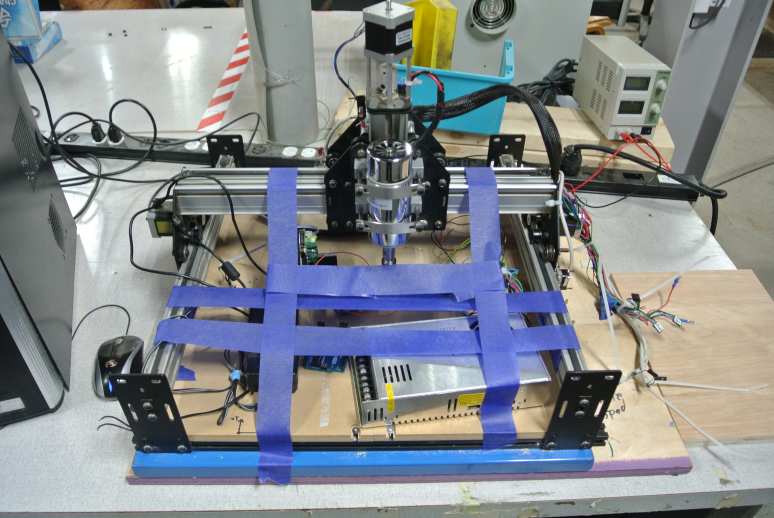

The Electronic Guts and Entrails

Sorted Out Components

The Mechanical Beast

Post Work Cleanup and Marking

Preliminary List of Needs

Hardware

- Cables need to be labeled

- Cables need to be consistent gage and type

- Connectors need to be keyed (so they only fit together one way) and standardized

- Cable routing and securing needs to be redone

- If wire ties are used, they need to be trimmed

- Limit switches need to be securely mounted and wired

- Mounting hardware for table is missing a nut

- Attach spindle to keyed connector

- Control boards need to be tested

- Stepper motors need to be tested

- Determine heat sink and cooling fan needs for control boards

- Determine whether control board interfaces with spindle

- Research alternatives for controllers and connectors

- Research alternatives for table materials & mounting

Software

Note: This section will be expanded when hardware issues are fixed.

- Determine whether min/max limits are stored

- Determine optimum software versions and document all settings