Difference between revisions of "Alpha Spark Detector"

| Line 23: | Line 23: | ||

* Power Supply for CCFL Case MOD Lights | * Power Supply for CCFL Case MOD Lights | ||

[[File:Tms_CCFL_Power_Supply_Covered.jpg]] | [[File:Tms_CCFL_Power_Supply_Covered.jpg]] | ||

| − | |||

| − | |||

* Thin Copper Wire | * Thin Copper Wire | ||

* Wire | * Wire | ||

Revision as of 22:55, 12 October 2012

Contents

Why

Radiation is all around. And the Truely Mad Scientist's LVL1 Splinter Group wants to detect it all. For this build, the radiation being detected is alpha radiation. Alpha radiation consists of alpha particles ejected from a decaying atom. The particle consists of two protons and two neutrons. The particle is essentially a helium atom nuclei and carries a positive charge. The positive charge allows for its identification and detection.

The Build

The Bill of Materials:

- Single Row Header Pins

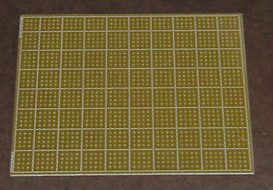

- Strip Board

- Acrylic Sheet (0.093, 0.22, 0.05 inches thicknesses)

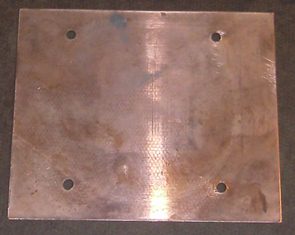

- Copper Sheet

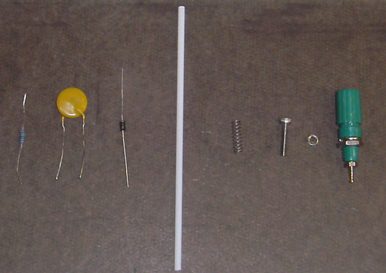

- 1 watt 10 Mega Ohm Resistor

- 0.01 uf Ceramic Disc Capacitor 2kv rating (qty 2)

- 1N4007 Diode (qty 12)

- Stirring Straws

- Springs (qty 4)

- Nuts and Bolts (qty 4 each)

- Terminal Connector

- Power Supply for CCFL Case MOD Lights

- Thin Copper Wire

- Wire

- Super Glue

- Hot Glue

The Components:

- Sensor Assembly

- Voltage Multiplier

- Power Supply

- Housing

Assembly

Sensor Assembly

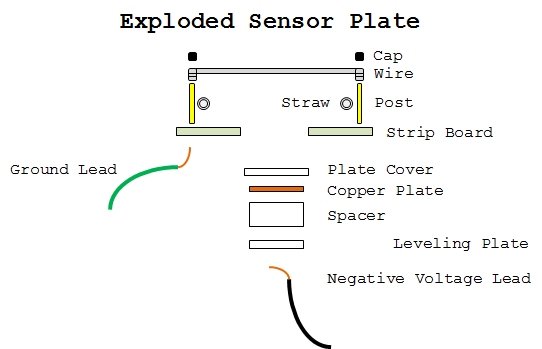

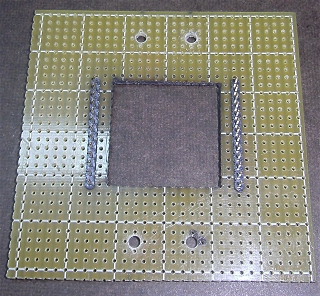

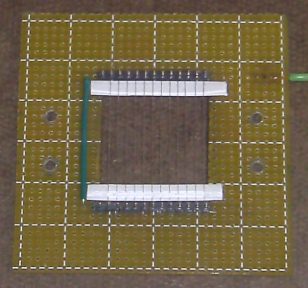

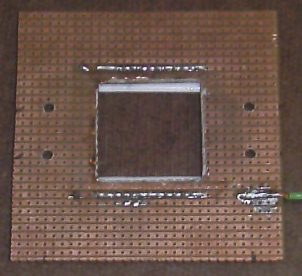

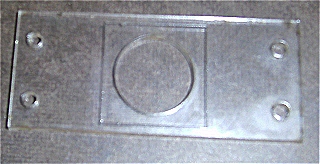

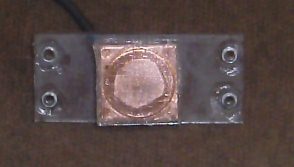

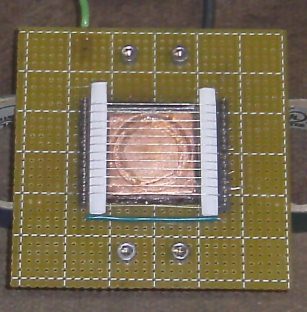

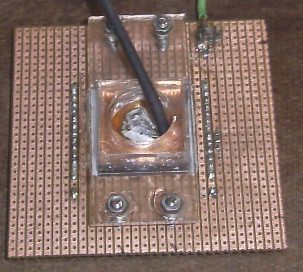

The Sensor Plate illustrated above is assembled in layers. The top layer consists of header pin spacers which are used to hold the sensor wires inplace. The sensor wires are wirewrapped to rows of header pin posts. Below the wires are straws which will tension the wire when assembled. This wire assembly is soldered onto a strip board with a square cut out of the center to allow the bottom elements to be adjusted in height and leveling. The bottom assembly begins with a Cover Plate designed to shield the Copper Plate's corner which collect charge and interfer with the operation. The Copper Plate is mounted on a Spacer with a through hole to allow the Negative Voltage Wire to be attached. The Leveling Plate also has an access hole for the Negative Voltage Wire and serves as the mounting for the bottom assembly. Finally, the Negative Voltage wire is soldered to the Copper Plate and the Ground Wire is soldered to the header pin posts. Not visible in the diagram are the four leveling screws through the Strip Board and fastened to the Leveling Plate with springs in between. A wire is also used to jumper/connect the two rows of header pin posts.

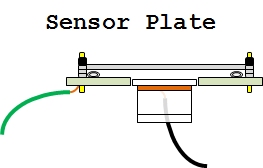

This assembled diagram shows the straws, flattened by the wires, providing tension.

Sensor Top Assembly

Sensor Bottom Assembly

Sensor Complete Assembly

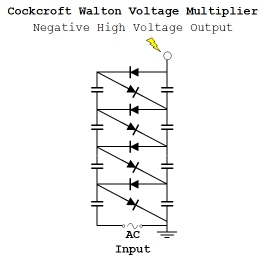

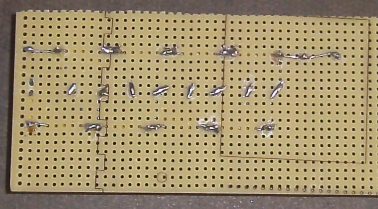

Voltage Multiplier

This voltage multiplier has eight stages and generates Negative high voltage. The capacitors are 0.01uf ceramice rated at 2kv. The circuit uses pairs of diodes in series to represent a single diode in the diagram. The circuit is soldered wire-to-wire on perf-board.

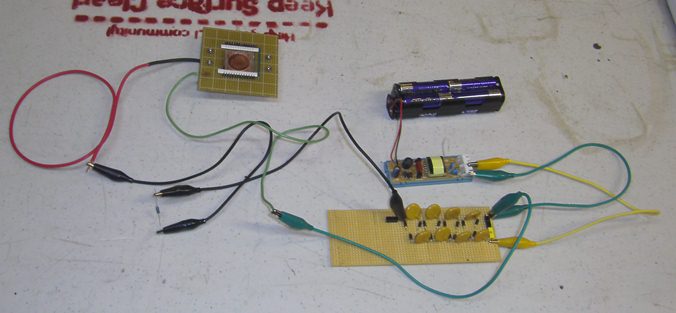

Power Supply

The power supply used is a common Cold Cathode Fluorescent (ccfl) Tube driver used in computer case mods. The output is rated at 900 volts ac and can drive two CCFL tubes.

Wired Together

The detector is wired up as shown in the image below. A 10 mega ohm resistor is put in series with the Copper Plate and Voltage Multiplier.

Housing

Operation

After the detector is powered on, it maybe necessary to adjust the distance between the Copper Plate and Overhead Wires. The leveling Screws are turned until any arcing between the copper plate and wires stops. The seperation is intended to be the minimum distance that does NOT arc on its own.

Once adjustments are made, an alpha emitter sample is placed above the Sensing Wires with the direction of alpha emmision directed toward the Sensing Wires and Copper Plate. When an alpha source is present, a spark jumps between the Sensing Wires and Copper Plate. The stronger the source, the more sparks are generated. The arcing should generate an audible snapping sound.

If a known alpha source does not generate the sparks then it maybe necessary to adjust the distance between the Sensing Wires and Copper Plate. Adjust the Leveling Screws to reduce the distance but not enough to allow spontaneous sparking in the sensor.