Difference between revisions of "Murphy"

| (31 intermediate revisions by 4 users not shown) | |||

| Line 11: | Line 11: | ||

= General Info = | = General Info = | ||

| − | + | Murphy is a franken-taz that has been upgraded piece by piece from a stock taz-3. It currently has the Taz 5 hexagon v2 hotend with .5mm nozzle attached. Murphy can handle a variety of materials, but is configured by default for PLA. Murphy requires 3mm filament. Murphy can print from SD card or the Ubuntu workstation to the left. | |

| − | + | Because it is not stock, some settings in the firmware are custom. Please exercise caution (or refrain from) when uploading firmware. | |

| − | + | '''Space filament is $.10 a gram. All filament used, failed or successful must be weighed and paid for''' | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Scale is on right of station, money goes in lockbox as labeled. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | == | + | = Getting Started = |

| − | |||

| − | |||

| − | |||

| − | == | + | '''Never''' assume the machine has been left in an ideal state. The machine is available not just to members but to the general public as well. |

| − | + | ||

| + | Kevin's bare minimum workflow before printing: | ||

| + | |||

| + | # Launch Cura | ||

| + | # Load Model | ||

| + | # Verify settings | ||

| + | # Verify Calibration | ||

| + | # Check Filament | ||

| + | # Level Bed | ||

| + | # Check Extrusion | ||

| + | # Verify Filament is Not Crossed | ||

| + | # Print | ||

| + | |||

| + | If you have a large or long print to run, it is recommended to run a small calibration cube first to verify that the settings are correct. | ||

| + | |||

| + | = Cura = | ||

| + | [[File:launchcura.png|500px]] | ||

| + | |||

| + | Launch Cura by clicking it's icon in the quick launcher | ||

| + | |||

| + | = Print Material Profiles = | ||

| + | |||

| + | The TAZ can print a variety of materials, but the two most common are PLA and ABS. PLA is much easier to work with, while ABS is sturdier and more resistant to heat. Murphy is configured to print PLA by default. For printing purposes, PLA uses a lower bed and extruder temperature. Spools should be labeled, but the following video can help you identify unlabeled filament: | ||

| + | https://www.youtube.com/watch?v=zqanb6mH-xU | ||

| + | |||

| + | Lulzbot maintains a list of profiles for the taz: | ||

| + | |||

| + | https://www.lulzbot.com/taz-5-cura-profiles | ||

| + | |||

| + | = Pre-Print = | ||

| + | |||

| + | Following these steps gives you a better chance of success: | ||

| + | |||

| + | == Software == | ||

| + | |||

| + | === 1. Load Model === | ||

| + | |||

| + | [[File:loadmodel.png|500px]] | ||

| + | |||

| + | === 2. Arrange/Manipulate Model === | ||

| + | Left click on your model to enable options for scaling, resizing, rotating, etc. | ||

| + | |||

| + | [[File:Clickmodel.png|500px]] | ||

| + | |||

| + | Right clicking on your model gives additional more advanced options | ||

| + | |||

| + | |||

| + | === 3. Verify Settings === | ||

| + | |||

| + | By default a PLA profile should be loaded. If you did not launch Cura yourself, this is not guaranteed. Verify these settings: | ||

| + | |||

| + | [[File:Basictaz.png]][[File:Advancedtaz.png]] | ||

| + | |||

| + | |||

| + | === 4. Launch Control Panel === | ||

| + | |||

| + | Click the control button at the top of the screen. Make sure to select the correct device in the dialog the follows | ||

| + | |||

| + | [[File:Launchcontrol.png|500px]] | ||

| + | |||

| + | Final Software Considerations | ||

| + | |||

| + | Do you need rafts or supports? A raft can help with bed adhesion, while supports can help with troublesome overhangs. Should you cut your model in half to have more area on the bed, and glue it together afterword. | ||

| + | |||

| + | == Physical Equipment == | ||

| + | |||

| + | === 1. Load Filament === | ||

| + | |||

| + | Official loading filament video from Aleph: | ||

| + | |||

| + | https://www.youtube.com/watch?v=xpT5j2pZVeQ | ||

| + | |||

| + | === 2. Verify Idler Tension === | ||

| + | |||

| + | The idler latch has two adjustable bolts. On the right side of the latch, there are two bolts for adjusting tension. The washers separating the springs should be 5mm apart or less. | ||

| + | |||

| + | === 3. Level the Bed === | ||

| + | |||

| + | Aleph's "A4 paper" method for leveling the bed: | ||

| + | |||

| + | https://www.youtube.com/watch?v=EdB8jbXFfns | ||

| + | |||

| + | === 4. Check Extrusion === | ||

| + | |||

| + | Set an extrusion temperature (200 for PLA, 250 for ABS). When the hotend reaches the target temperature, click the extrude button until filament extrudes. If it does not extrude, check for an unfixed or unreported jam, and verify material type and idler tension. | ||

| + | |||

| + | [[File:Tazcontrol.png|500px]] | ||

| + | |||

| + | = Print = | ||

| + | |||

| + | It's recommended to stay close for the first few layers. Most prints fail because of adhesion or lamination issues. Remember, when using lvl1's filament you must pay for failed prints, so stopping a failed print as early as possible saves you money. | ||

| + | |||

| + | = Trouble Shooting = | ||

| + | |||

| + | It Jammed | ||

| + | |||

| + | Clean Hobbed Bolt | ||

| + | |||

| + | Check Fans | ||

| + | |||

| + | Machine Calibration | ||

| + | |||

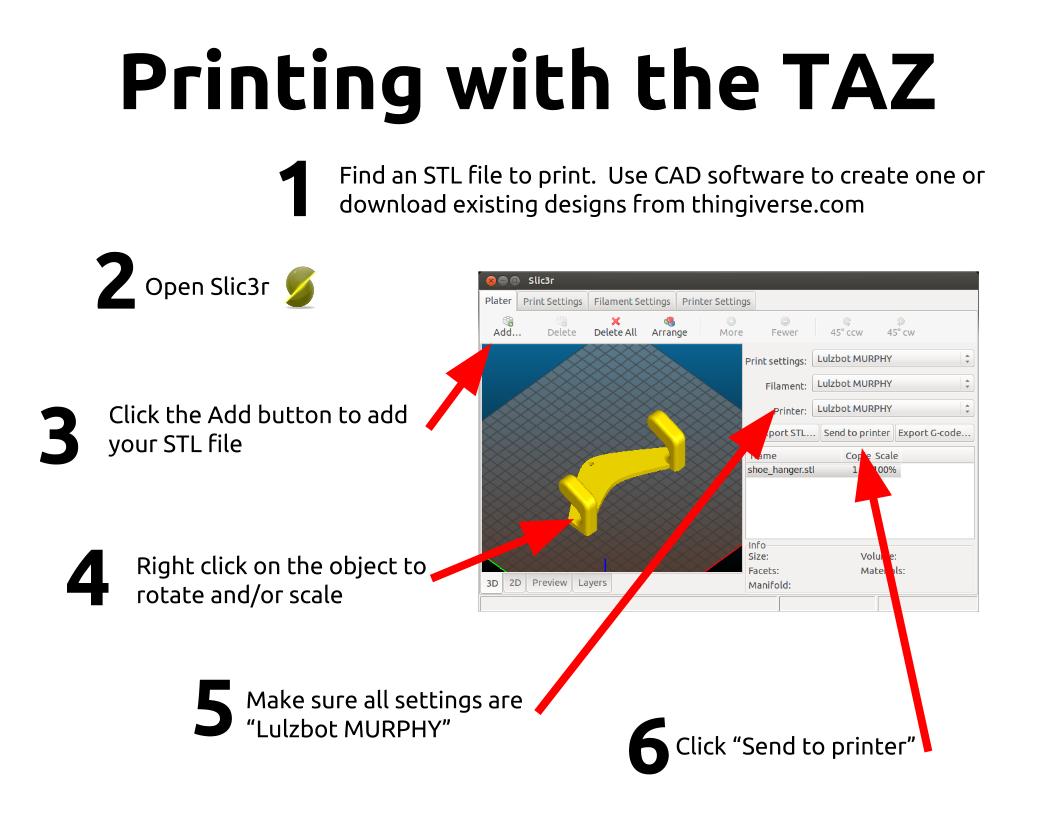

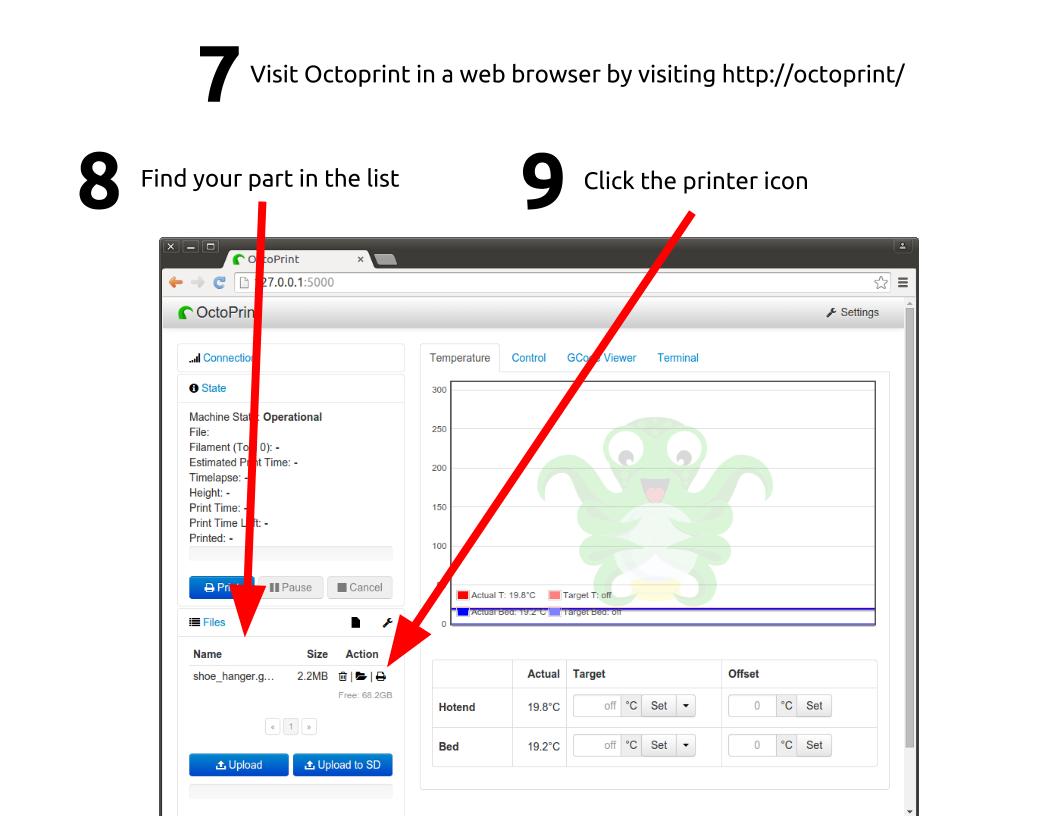

| + | = Deprecated - How to use = | ||

| + | [[File:Howtotaz1.jpg]] | ||

| + | |||

| + | [[File:Howtotaz2.jpg]] | ||

Latest revision as of 16:50, 6 September 2016

[Equipment|Back to list of Equipment]]

|

Contents

General

|

General Info

Murphy is a franken-taz that has been upgraded piece by piece from a stock taz-3. It currently has the Taz 5 hexagon v2 hotend with .5mm nozzle attached. Murphy can handle a variety of materials, but is configured by default for PLA. Murphy requires 3mm filament. Murphy can print from SD card or the Ubuntu workstation to the left.

Because it is not stock, some settings in the firmware are custom. Please exercise caution (or refrain from) when uploading firmware.

Space filament is $.10 a gram. All filament used, failed or successful must be weighed and paid for

Scale is on right of station, money goes in lockbox as labeled.

Getting Started

Never assume the machine has been left in an ideal state. The machine is available not just to members but to the general public as well.

Kevin's bare minimum workflow before printing:

- Launch Cura

- Load Model

- Verify settings

- Verify Calibration

- Check Filament

- Level Bed

- Check Extrusion

- Verify Filament is Not Crossed

If you have a large or long print to run, it is recommended to run a small calibration cube first to verify that the settings are correct.

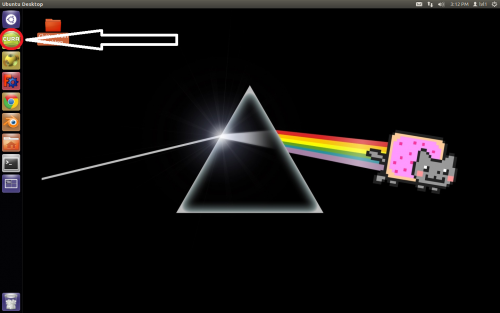

Cura

Launch Cura by clicking it's icon in the quick launcher

Print Material Profiles

The TAZ can print a variety of materials, but the two most common are PLA and ABS. PLA is much easier to work with, while ABS is sturdier and more resistant to heat. Murphy is configured to print PLA by default. For printing purposes, PLA uses a lower bed and extruder temperature. Spools should be labeled, but the following video can help you identify unlabeled filament: https://www.youtube.com/watch?v=zqanb6mH-xU

Lulzbot maintains a list of profiles for the taz:

https://www.lulzbot.com/taz-5-cura-profiles

Pre-Print

Following these steps gives you a better chance of success:

Software

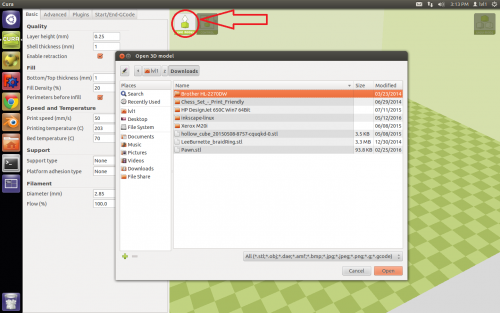

1. Load Model

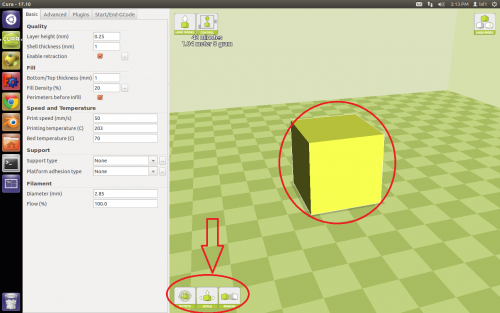

2. Arrange/Manipulate Model

Left click on your model to enable options for scaling, resizing, rotating, etc.

Right clicking on your model gives additional more advanced options

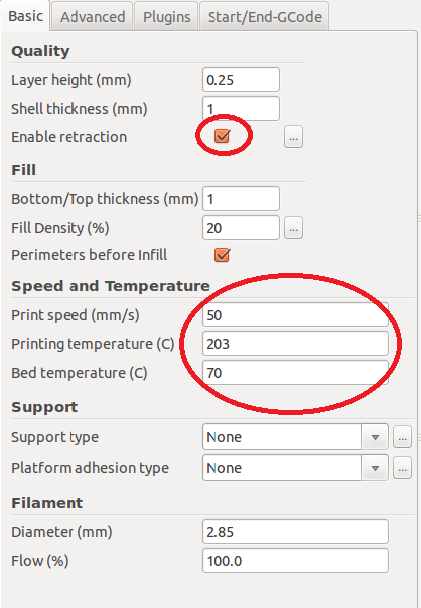

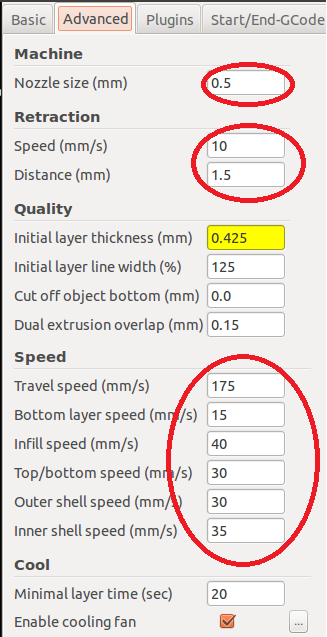

3. Verify Settings

By default a PLA profile should be loaded. If you did not launch Cura yourself, this is not guaranteed. Verify these settings:

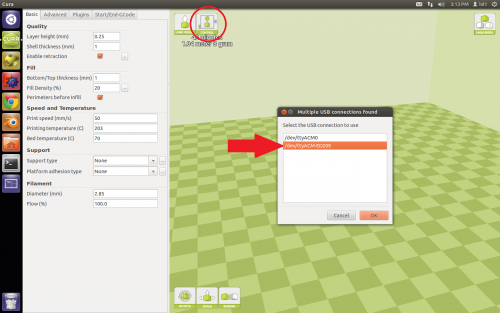

4. Launch Control Panel

Click the control button at the top of the screen. Make sure to select the correct device in the dialog the follows

Final Software Considerations

Do you need rafts or supports? A raft can help with bed adhesion, while supports can help with troublesome overhangs. Should you cut your model in half to have more area on the bed, and glue it together afterword.

Physical Equipment

1. Load Filament

Official loading filament video from Aleph:

https://www.youtube.com/watch?v=xpT5j2pZVeQ

2. Verify Idler Tension

The idler latch has two adjustable bolts. On the right side of the latch, there are two bolts for adjusting tension. The washers separating the springs should be 5mm apart or less.

3. Level the Bed

Aleph's "A4 paper" method for leveling the bed:

https://www.youtube.com/watch?v=EdB8jbXFfns

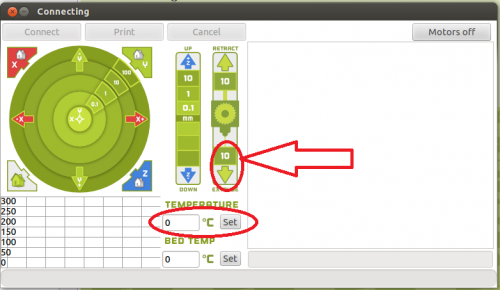

4. Check Extrusion

Set an extrusion temperature (200 for PLA, 250 for ABS). When the hotend reaches the target temperature, click the extrude button until filament extrudes. If it does not extrude, check for an unfixed or unreported jam, and verify material type and idler tension.

It's recommended to stay close for the first few layers. Most prints fail because of adhesion or lamination issues. Remember, when using lvl1's filament you must pay for failed prints, so stopping a failed print as early as possible saves you money.

Trouble Shooting

It Jammed

Clean Hobbed Bolt

Check Fans

Machine Calibration